Total Blender Volume: 3500 Liters

Main Motor Power: 22 kW (Siemens, energy-efficient)

Mixing Speed: Variable 0–27 rpm (frequency-controlled)

Construction Material: 100% Food-Grade SS304

Discharge Method: Bottom DN200 butterfly valve (residue-free design)

Safety System: Interlocking safety grid – ensures machine stops when protective screen is out of place

| Availability: | |

|---|---|

| Quantity: | |

WLDH-3500

Karvil

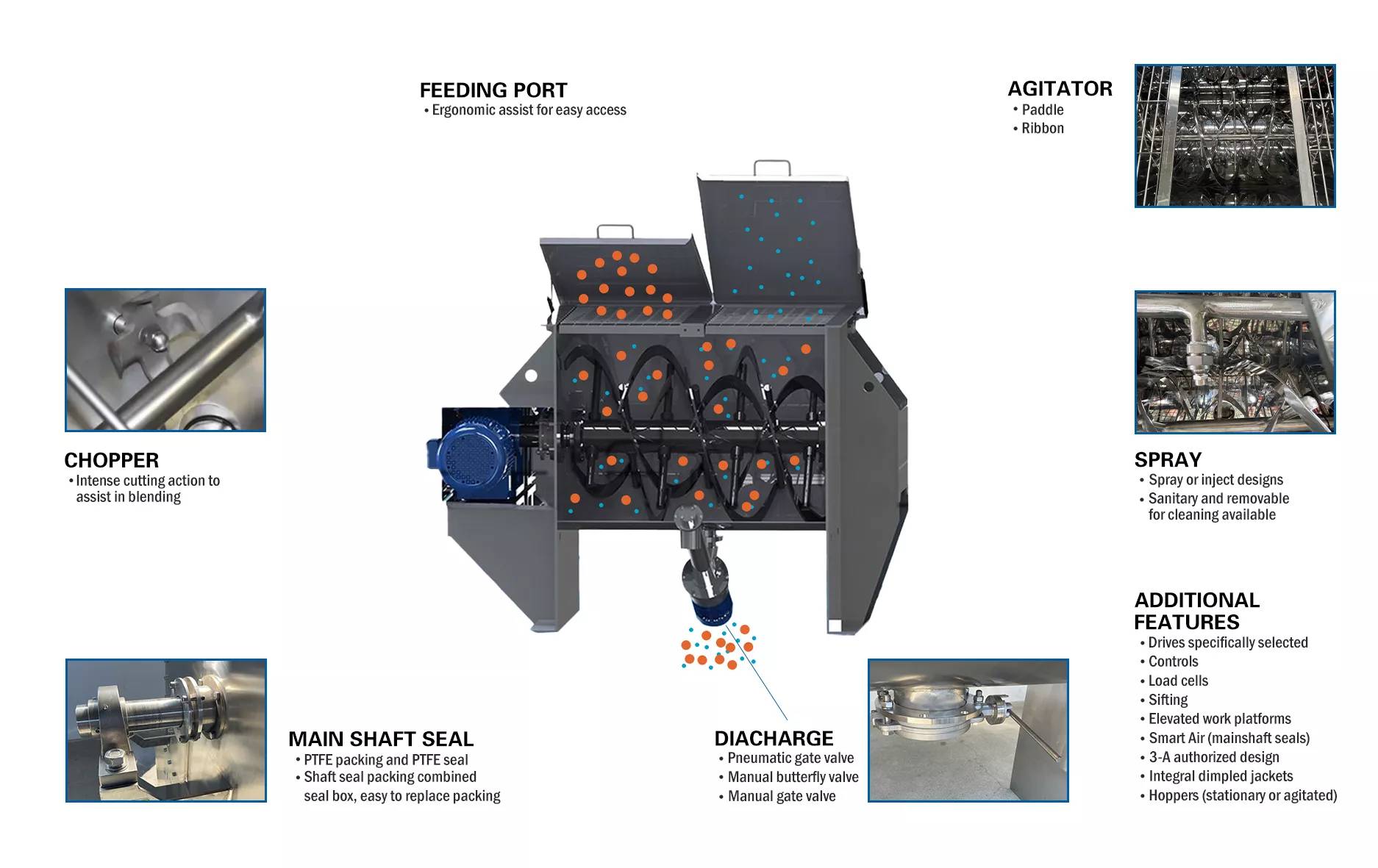

Ribbon Blender with Feeding & Packing System

3500L Nutraceutical Powder Processing Line – Complete Stainless Steel Mixing & Automated Packing System

Karvil Machinery delivers a comprehensive powder processing line for the health supplement and nutrition industry. This advanced system integrates a 3500L horizontal ribbon mixer, precise feeding conveyors, and dual-stage packaging machines. Built entirely with food-grade stainless steel 304, it guarantees hygienic production, high throughput, and safe operation.

Mixer Capacity:

The horizontal ribbon blender features a gross volume of 3500 liters, engineered for high-volume batch processing. The working capacity is approximately 2100 liters, allowing ample space for efficient and uniform mixing.

Drive System:

Equipped with a 22 kW Siemens motor, the system ensures consistent torque and stable performance during heavy-load mixing operations.

Speed Control:

The mixing shaft operates within a range of 0 to 27 revolutions per minute, governed by a variable frequency drive (VFD) for smooth adjustment and better process control.

Material of Construction:

All components in contact with product are fabricated from food-grade SUS304 stainless steel, ensuring compliance with hygiene and food safety standards. The inner surfaces are mirror polished, while the outer surfaces feature a satin brushed finish for easy cleaning and corrosion resistance.

Discharge Mechanism:

Integrated with a bottom-mounted manual butterfly valve (DN200). The discharge port is designed to prevent any material buildup or residue retention inside the chamber.

These angled screw conveyors are responsible for transporting the blended powder from the discharge point of the mixer to the next stage without manual handling.

This precision dosing machine uses two intermeshing auger screws to achieve accurate and repeatable filling of nutraceutical or dietary powder blends into bags or containers.

Links the filling system with the next packaging phase, reducing manual handling and enabling continuous flow.

Handles downstream packaging tasks such as bulk repackaging, bag sealing, or outer-bagging of small packets.

Complete Integration: All-in-one system from mixing to final packaging

Hygienic Design: Food-safe stainless steel ensures compliance with FDA and GMP standards

Labor Efficiency: Automation reduces manual handling and increases throughput

User-Friendly Control: Centralized PLC-based operation for all components

Dust-Free Operation: Enclosed conveyors and tight-seal packaging reduce powder loss

Customizable Options: Bag sizes, filling weights, and discharge formats adjustable upon request

Built-in Safety: Intelligent interlock ensures secure operation during loading/unloading

Technical Parameters

This production line is engineered to meet the strict standards of the food and health product industries. It is ideal for:

Nutritional powder blends

Dietary supplements (protein, vitamin mix)

Herbal or botanical powder processing

Functional food powders

Sports nutrition formulations

Whether you're scaling up or seeking a GMP-compliant solution for high-volume powder production, this line offers outstanding reliability and performance.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.