WLDH-300

Customizable Design

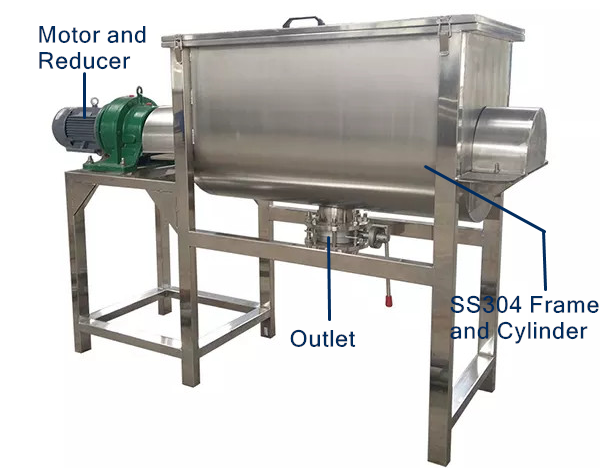

The mixer can be made with all stainless steel or materials contact part with stainless steel or all carbon steel.

Interior Surfaces: Mirror polished.

Discharge: Manual valve or pneumatic valve.

Safety device:Safety grid on the cylinder. Emergency stop device when the lid is open while the safety grip is not on the cylinder

Heating function ( optional): Electric heating with jacket for heating transfer oil; Jacket for steam; Jacket for water circulation.

Cooling function( optional): Jacket for cooling water circulation or equipped together with a chiller.

Vacuum function( optional): it includes vacuum pump, metal hose, buffer tank and vacuum gauge. Vacuum degree can reach-0.096mpa.

Other customized function can be discussed.

Technical Parameters

Features

Continuous Material Feeding: The integrated feeder system allows for a continuous and automated feeding of raw materials into the mixing chamber. This ensures a consistent and uninterrupted mixing process.

Horizontal Mixing Design: The horizontal layout of the mixer promotes thorough and even distribution of materials, ensuring a homogenous blend.

Ribbon or Paddle Agitator: Depending on the specific application, these mixers can be equipped with ribbon or paddle agitators that provide effective and gentle mixing action.

Customizable Configurations: Horizontal mixers with feeders come in various sizes and configurations to accommodate different batch sizes and production requirements.

Materials Handling: They are suitable for a wide range of dry materials, including food ingredients, chemicals, pharmaceutical powders, and more.

Precision Control: Many models feature advanced control systems that allow operators to regulate feeding rates, mixing speed, and other parameters for precise and consistent results.

Ease of Maintenance: These systems are designed for easy cleaning, maintenance, and quick access to components, minimizing downtime.

Applications

Food Processing: Ideal for blending dry food ingredients like flours, spices, and additives in a continuous production setting.

Pharmaceutical Manufacturing: Used for homogenizing pharmaceutical powders and granules to produce tablet or capsule formulations.

Chemical Industry: Suitable for mixing and blending dry chemical substances for various chemical processes.

Plastics and Polymers: Used in the plastics industry for mixing plastic resins and additives for molding and extrusion processes.

Cosmetic and Personal Care: Suitable for blending dry cosmetic ingredients to produce skincare, haircare, and makeup products.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.