WLDH-1500

Customizable Design

The mixer can be made with all stainless steel or materials contact part with stainless steel or all carbon steel.

Interior Surfaces: Mirror polished.

Discharge: Manual valve or pneumatic valve.

Safety device:Safety grid on the cylinder. Emergency stop device when the lid is open while the safety grip is not on the cylinder

Heating function ( optional): Electric heating with jacket for heating transfer oil; Jacket for steam; Jacket for water circulation.

Cooling function( optional): Jacket for cooling water circulation or equipped together with a chiller.

Vacuum function( optional): it includes vacuum pump, metal hose, buffer tank and vacuum gauge. Vacuum degree can reach-0.096mpa.

Other customized function can be discussed

Technical Parameters

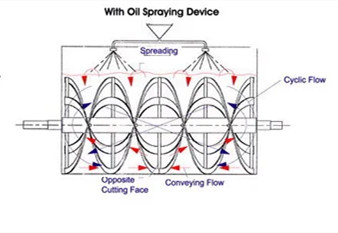

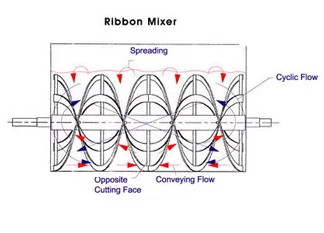

Working Principle

Application Industry

Ribbon mixers are incredibly versatile and find applications across various industries due to their ability to efficiently blend dry powders, granules, and other solid materials. Some of the industries where ribbon mixers are commonly used include:

Food Processing: Ribbon mixers are extensively used in the food industry for blending ingredients like spices, seasonings, flour, baking mixes, powdered beverages, cereals, and nutritional supplements. They ensure uniform distribution and consistent blending of food products.

Pharmaceuticals: In pharmaceutical manufacturing, ribbon mixers are utilized for blending powdered medications, excipients, granules, and other pharmaceutical ingredients. They ensure uniform mixing and consistent dosage in final products.

Chemicals: Ribbon mixers play a crucial role in chemical manufacturing for blending various dry chemical compounds, dyes, pigments, fertilizers, powdered detergents, and other chemical formulations.

Plastics and Polymers: Industries involved in plastics and polymers use ribbon mixers to blend polymer additives, colorants, fillers, and powdered resins to achieve homogeneity in plastic formulations.

Cosmetics and Personal Care: Ribbon mixers are employed in the manufacturing of cosmetics, toiletries, and personal care products for blending powdered ingredients like talc, pigments, powders for creams, and lotions.

Construction Materials: In the construction industry, ribbon mixers are used to blend dry materials such as cement, mortar, plaster, and various construction chemicals to ensure consistent mixtures and improved workability.

Chemical Engineering: Ribbon mixers are also applied in chemical engineering processes for mixing powders, catalysts, and other materials used in chemical reactions or processes.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.