Customization Options

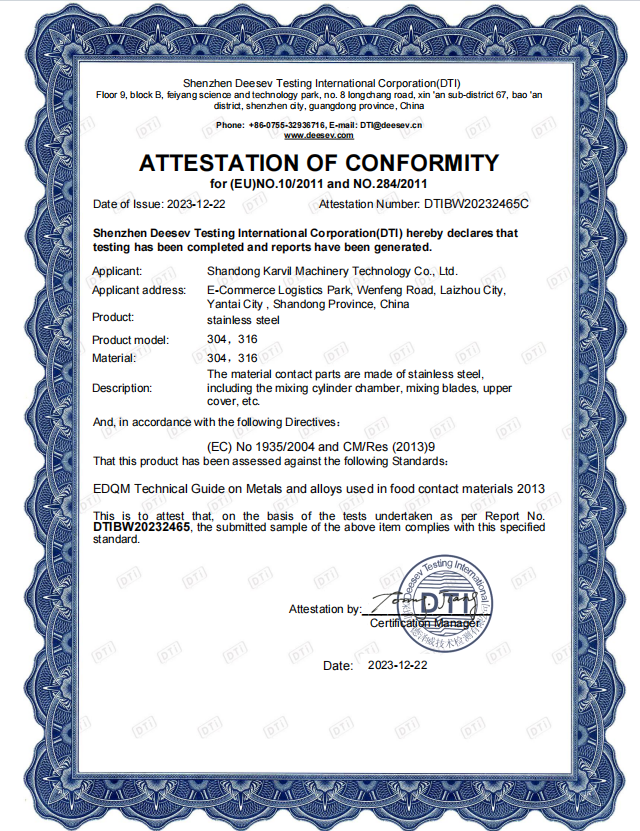

Material:SS304, SS316 with mirror polished or carbon steel

Discharge Method: hydraulic tilting discharging or screw extrusion discharging or both of them.

Vacuum function:it includes vacuum pump, metal hose, buffer tank and vacuum gauge. Vacuum degree can reach-0.096mp

Heating function:Electric heating with far ultrared heaters or with jacket for heating transfer oil; Jacket for steam; Jacket for water circulation.

Cooling function:Jacket for cooling water circulation or equipped together with a chiller.

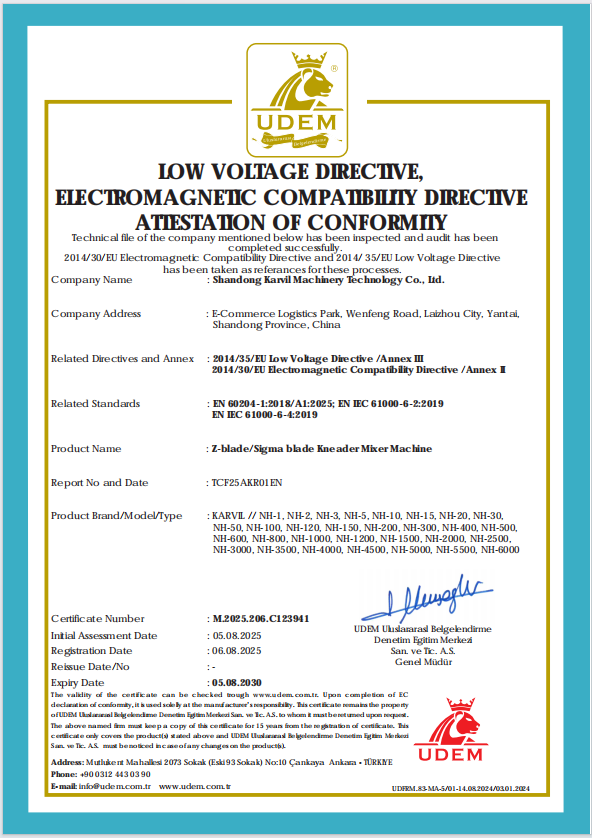

Others: PLC system, HMI,Schneider electronic components,Circuit breaker protection,Voltage & current showed and etc

Karvil Machinery Sigma Mixer

Sigma mixer is also known as the z blade mixer or sigma kneader mixer, which is used for kneading, and mixing of high-viscosity materials. Sigma mixer is employed across diverse industries, including chemical, pharmaceuticals and food, due to its ability to effectively mix materials with high viscosities such as silicone rubber, adhesive, graphite and chewing gum.

It is available in varioussizes, from smaller laboratory scale units to larger industrial ones, and are equipped with features for precise control over speed, temperature, vacuum, and mixing duration.

Karvil Sigma Mixer offers the advantage of a reliable, durable, and efficient mixing solution tailored to meet the specific requirements of various industries, ensuring consistent and high-quality output.

Advantages of Sigma Mixer

Karvil has a professional technical team and has already sold our equipment to over 40 countries all over the world as well as different industries. Karvil has rich technical experience in different applications and also good after sale ability to provide efficient, accurate service

Efficient Mixing:

Sigma mixers are equipped with dual counter-rotating blades (sigma blades), which intermesh closely to provide thorough and efficient mixing of materials.

Versatility:

Sigma mixers are versatile and can handle a wide range of materials, including high-viscosity pastes, doughs, powders, slurries, and even highly abrasive or sticky materials.

High Capacity

Sigma mixers are available in various sizes and capacities, ranging from laboratory-scale models to large-scale industrial mixers capable of handling several tons of material per batch.

Process Control

Sigma mixers can be equipped with advanced control systems that allow operators to monitor and adjust mixing parameters such as speed, temperature, and mixing time.

Durable Construction

Sigma mixers are typically constructed from high-quality materials such as stainless steel, which ensures durability, corrosion resistance, and long service life.

Application

Ceramics

Chewing Gum

Adhesive and Sealant Manufacturing

Medicine

Silicone Rubber

Advantages of Karvil Machinery

Karvil Machinery combines technical expertise, advanced manufacturing, and a customer-focused approach to deliver high-quality, customizable, and reliable mixing solutions trusted by industries around the world

Extensive Industry Experience and Global Reach

Karvil has a professional technical team and has sold equipment to more than 40 countries worldwide, serving diverse industries such as chemical, pharmaceutical, and food. This broad experience ensures deep understanding of various application requirements.

High Quality and Reliable Performance

Karvil uses premium materials such as SS304, SS316, or carbon steel, and adopts Schneider electrical components to ensure stable operation, durability, and easy maintenance.

Strong Customization Capability

The company provides highly flexible customization options — including blade speed, heating/cooling methods, vacuum systems, and discharge types — to perfectly match different industrial processes and customer needs.

Comprehensive After-Sales and Technical Support

In addition to excellent manufacturing capabilities, Karvil offers efficient and accurate after-sales service, helping customers optimize their production processes and maintain consistent performance.

Contact Us

Discover how Karvil’s customized mixing solutions can enhance your production efficiency — contact us today for a tailored consultation!

Related Blogs

Sigma Mixer Troubleshooting Tips for Better Mixing Results

Sigma mixers are a vital part of industries like food, pharmaceuticals, and chemicals. They excel at mixing high-viscosity materials and ensuring consistent results. However, even the most reliable mixers can experience issues that affect their performance.In this article,

Read MoreHow To Choose The Right Sigma Mixer Size And Capacity

Sigma mixers are vital in industries like food, pharmaceuticals, and chemicals. They efficiently mix high-viscosity materials, but choosing the right size and capacity can be challenging. In this article, we’ll explore the key factors that affect your Sigma mixer selection.

Read MoreA Complete 10-Unit Mixing Ecosystem Sigma Mixers Heading To Turkey

It is not often that we get to manufacture a client’s entire production line in one go—from the R&D lab bench all the way to the factory floor.This week, we completed a specialized fleet of 10 Sigma Kneaders for a chemical manufacturer in Turkey. Their application? A complex, high-viscosity blend of

Read MoreTop Sigma Mixer Features Buyers Must Evaluate First

Sigma Mixers are indispensable in industries such as food, pharmaceuticals, and chemicals. They excel at efficiently mixing high-viscosity materials like adhesives, rubber, and dough. In this article, we’ll explore the top features you must evaluate before purchasing a Sigma Mixer.

Read More

Get Free Quote

Contact Info

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.

+86-189 5324 6528