Views: 0 Author: Site Editor Publish Time: 2025-12-03 Origin: Site

Sigma mixers are vital in industries like food, pharmaceuticals, and chemicals. They efficiently mix high-viscosity materials, but choosing the right size and capacity can be challenging. In this article, we’ll explore the key factors that affect your Sigma mixer selection. You’ll learn how to match the mixer size to your batch size, material properties, and production needs. By the end, you’ll be equipped to make an informed decision and optimize your production process.

Batch Size Considerations: Match the mixer size with your typical batch volume, ensuring it operates at 60%-70% of capacity for optimal performance.

Material Properties: Choose a mixer that can handle the specific viscosity, abrasiveness, and chemical composition of your materials.

Cost vs. Efficiency: Balance the upfront cost of the Sigma mixer with long-term savings from energy efficiency, reduced maintenance, and improved mixing quality.

Customization and Features: Explore additional features such as temperature control systems, automation, and customizable discharge mechanisms to enhance your mixing process.

Support and After-Sales: Choose a reliable manufacturer, like Karvil Machinery, that offers strong customer support, training, and readily available spare parts.

A Sigma mixer is a specialized mixing machine that uses two counter-rotating Z-shaped blades. These blades work in unison to knead, shear, and fold high-viscosity materials, such as rubber, adhesives, and pastes, to create a homogenous mixture. The mixer operates within a cylindrical chamber, which is often jacketed for heating or cooling purposes. This setup makes Sigma mixers ideal for processing thick materials that require high shear forces to achieve a uniform blend.

The primary function of the Sigma mixer is to handle materials that are challenging to mix with traditional machines. The counter-rotating motion of the blades ensures that the materials are thoroughly mixed without leaving any unmixed pockets. As the blades rotate, they stretch, fold, and compress the materials repeatedly, ensuring even distribution of ingredients. The Sigma mixer’s robust design makes it well-suited for heavy-duty industrial applications, where mixing efficiency and product consistency are critical.

Sigma mixers come in different configurations, with the most common being the Z-type mixers and double-helix mixers. Z-type mixers are widely used in industries that require high shear mixing, such as in the production of adhesives, rubber compounds, and food doughs. Double-helix mixers, on the other hand, use two helical blades that rotate in opposite directions. This configuration is typically used in industries where gentler mixing is required, such as pharmaceuticals and food production.

In addition to these standard models, some Sigma mixers are equipped with vacuum systems to remove air from the mixture. This feature is beneficial for air-sensitive materials, as it helps prevent the introduction of air pockets and ensures a uniform blend. Other advanced models come with temperature control jackets that can heat or cool the materials as they are mixed. These options provide additional flexibility and can be essential for certain applications, such as the production of sensitive chemical formulations or food products that require precise temperature management.

The batch size is one of the most important factors when selecting a Sigma mixer size. For efficient mixing, the mixer should be capable of handling your typical batch size without being over- or under-loaded. Typically, the mixer should hold between 60%-70% of its total capacity to allow for adequate mixing space. This ensures that materials move freely within the chamber, allowing the blades to work effectively.

For smaller-scale operations, a Sigma mixer with a capacity ranging from 1L to 10L may suffice. However, larger operations, such as those in the chemical or rubber industries, may require mixers with capacities ranging from 500L to several thousand liters. It’s also essential to consider future scalability. If your production volume is expected to increase, choosing a slightly larger model can help accommodate future growth without requiring an immediate upgrade.

The properties of the materials being mixed will significantly influence the size and design of the Sigma mixer you choose. For high-viscosity materials like adhesives and rubber, a larger mixer with a more powerful motor and reinforced blades is necessary. These materials require more torque to be mixed properly, and the mixer should have the capacity to generate the required shear forces.

The chemical composition and abrasiveness of the materials also play a role in selecting the right mixer. For instance, highly corrosive materials, such as acids or chemicals, require mixers made from corrosion-resistant materials like stainless steel. Karvil Machinery offers Sigma mixers made from SS304 and SS316 stainless steel, which are ideal for handling corrosive materials in industries like pharmaceuticals and food processing.

Before selecting a Sigma mixer, it is essential to assess the space available in your facility for installation. Sigma mixers come in a variety of sizes, from small, laboratory-scale units to large industrial machines. It’s crucial to ensure that the selected mixer will fit within your production line while leaving room for any necessary auxiliary equipment such as feeding systems and conveyors.

The footprint of the Sigma mixer will vary based on its capacity and configuration. Compact models with a smaller footprint are available for laboratories and smaller operations. Larger industrial mixers, especially those with capacities exceeding 500L, require more space for proper installation and operation. Consideration of the available space will help you avoid costly modifications to your facility layout.

It is critical to match your mixer’s capacity with the typical batch size required for your production process. A Sigma mixer should operate at 60%-70% of its total capacity for optimal mixing. For example, if your typical batch size is 300L, a 500L Sigma mixer would be ideal, allowing enough room for materials to move freely during the mixing process.

Using a mixer that is too small for your batch size will lead to inefficiencies, as the material may not mix uniformly. Conversely, a mixer that is too large for your needs may result in wasted energy and increased operational costs. Selecting the right mixer size ensures that your mixing process remains efficient, consistent, and cost-effective.

When selecting a Sigma mixer, it’s essential to consider both current and future production needs. Smaller mixers, ranging from 1L to 10L, are ideal for lab-scale or small-scale operations where precision is more important than volume. However, for larger industrial operations, mixers with capacities between 100L and 5000L are typically required.

If your business is expanding, it may be worth opting for a mid-range mixer (e.g., 100L to 500L) that can meet current needs while leaving room for future growth. For high-volume, continuous production environments, larger mixers with capacities exceeding 1000L are more suitable. Karvil Machinery offers models up to 5000L, providing a variety of options to cater to different production scales.

Another key consideration when selecting a Sigma mixer is whether your production process is batch-based or continuous. Batch mixers are suitable for processes where materials are mixed in discrete quantities, such as in food or pharmaceutical production. These mixers are ideal for operations that do not require nonstop production.

On the other hand, continuous mixers are designed for high-volume production environments, where materials are mixed continuously. These mixers are often used in industries like rubber, chemicals, and adhesives, where large volumes of material need to be processed without interruption. Karvil’s continuous-flow Sigma mixers are designed to handle high-volume production while ensuring consistent and efficient mixing.

When mixing high-viscosity materials such as adhesives, rubber compounds, or pastes, a Sigma mixer with a larger capacity and more powerful motor is necessary. These materials require higher torque to ensure proper mixing, and the mixer must be equipped with strong blades capable of generating the required shear forces.

The motor power needed for high-viscosity materials typically ranges from 15 to 30 kW per 100L, depending on the mixer size. Karvil Machinery provides Sigma mixers with varying motor capacities to suit different material types, ensuring that even the most demanding applications are handled efficiently.

For lower-viscosity materials like powders or liquids, a smaller Sigma mixer with a less powerful motor may be sufficient. While low-viscosity materials do not require the same level of shear force, it’s still essential to maintain a consistent blending action to ensure uniformity.

Adjusting the motor speed and power allows the mixer to handle different material viscosities efficiently, ensuring high-quality mixing without excessive energy consumption. Sigma mixers equipped with variable frequency drives (VFD) can optimize energy use, adjusting the speed as needed based on the material's viscosity.

While the initial cost of a Sigma mixer can vary significantly based on its size and features, it’s important to consider the long-term investment value. Larger mixers with advanced features such as PLC controls and heating/cooling jackets come with a higher upfront cost. However, these features often result in long-term savings through increased efficiency, reduced maintenance, and improved product quality.

For businesses on a tighter budget, smaller mixers or basic models may be more affordable in the short term. However, opting for a higher-end model with energy-saving features and automated controls can provide better long-term value by reducing operating costs and downtime.

The material used to construct the Sigma mixer significantly impacts its overall cost. Stainless steel models, such as those made with SS304 or SS316, offer superior corrosion resistance and durability. These models are ideal for industries like pharmaceuticals and food processing, where hygiene and material protection are critical.

Carbon steel mixers are more affordable but may not offer the same level of protection against corrosive materials. If your production involves highly abrasive or corrosive substances, investing in a stainless steel model may be more cost-effective in the long run.

Choosing a Sigma mixer with a design that minimizes downtime and maintenance is crucial for cost-effectiveness. Opting for models with modular components and easy-to-replace parts can significantly reduce long-term maintenance costs. Additionally, mixers with energy-efficient motors and automation controls can reduce power consumption and operating expenses.

Karvil Machinery offers Sigma mixers with energy-saving features such as variable frequency drives (VFD), which optimize motor speed and power consumption, reducing overall energy costs.

Sigma mixers can be equipped with a range of additional features to optimize the mixing process. Temperature control systems, such as heating and cooling jackets, are essential for processing heat-sensitive materials. These jackets help maintain a consistent temperature throughout the mixing process, ensuring uniformity and preventing product degradation.

Karvil’s Sigma mixers can be customized with these temperature control systems to suit a variety of production requirements. Whether you need precise heating for chemical reactions or cooling for sensitive food products, customized features can help you achieve the desired results.

Integrating automation features like PLC systems and variable frequency drives (VFD) allows for precise control over the mixing process. These features improve efficiency by automating speed adjustments, mixing times, and temperature settings. Automation also reduces the need for manual intervention, leading to safer, more consistent operations.

Karvil’s Sigma mixers come with advanced automation options that can be tailored to your specific production needs, helping you achieve higher precision and reduced labor costs.

When selecting a Sigma mixer, consider the discharge mechanism that will work best for your materials. Hydraulic tilting or screw discharge mechanisms are common choices, each suited to different material consistencies. For example, thick pastes may require a screw discharge system to facilitate easy unloading, while liquid materials may benefit from a tilting mechanism.

Karvil offers customizable discharge options, including screw discharge systems and hydraulic tilting designs, to ensure seamless integration into your production workflow.

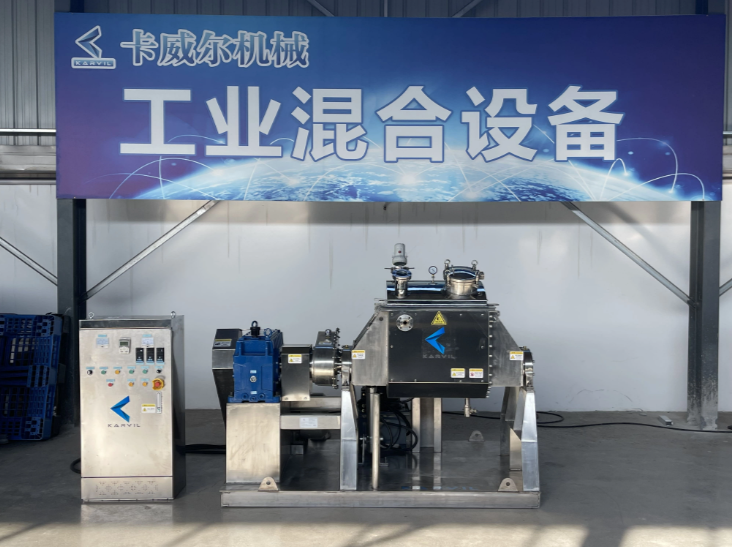

Choosing a reliable manufacturer is essential when purchasing a Sigma mixer. A reputable brand like Karvil Machinery offers strong customer support, spare parts availability, and training services to ensure your mixer operates at peak performance. With years of experience in the industry, Karvil provides tailored solutions and expert advice to help you select the right mixer for your needs.

Warranties and service contracts provide peace of mind, ensuring that your investment is protected. A good warranty covers repairs, parts replacement, and troubleshooting support, minimizing downtime and maintenance costs. Karvil’s Sigma mixers come with comprehensive warranties and after-sales support, ensuring that your production line runs smoothly for years.

Choosing the right Sigma mixer size and capacity is essential for optimizing your production process. By evaluating factors like batch size, material properties, and production needs, you can select the perfect mixer for your business. Investing in high-quality, customizable Sigma mixers with features like automation and temperature control ensures improved product consistency and quality.

KARVIL offers a range of Sigma mixers that cater to various production scales. Their customizable designs and advanced features provide long-term value, helping businesses stay efficient and adaptable. With KARVIL’s expert guidance, you can confidently select the best solution for your needs.

A: A Sigma mixer is a machine used to mix high-viscosity materials. It features two counter-rotating Z-shaped blades that shear and knead the materials to achieve uniform mixing.

A: To choose the right Sigma mixer, evaluate your batch size, material viscosity, and production volume. Match the mixer’s capacity to handle 60%-70% of the total batch for optimal performance.

A: Larger Sigma mixers allow for bigger batches, more efficient mixing, and scalability for growing production needs, ensuring consistent product quality.

A: High-viscosity materials require a more powerful Sigma mixer with stronger blades, while lower-viscosity materials can be mixed effectively with smaller, less powerful models.

A: Yes, Sigma mixers can be customized with features like temperature control, automated systems, and varying blade designs to meet specific production requirements.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.