Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

Sigma mixers are a vital part of industries like food, pharmaceuticals, and chemicals. They excel at mixing high-viscosity materials and ensuring consistent results. However, even the most reliable mixers can experience issues that affect their performance.

In this article, we will explore common problems, such as inconsistent mixing, excessive wear, and overheating. We will also offer practical solutions to address these challenges. Additionally, we will emphasize the importance of regular maintenance and troubleshooting to keep your Sigma mixer running smoothly, and introduce KARVIL's products to help improve your mixer’s performance and longevity.

Regular maintenance, including lubrication and temperature control, is crucial for ensuring optimal Sigma mixer performance.

Addressing common issues like inconsistent mixing and excessive wear early can prevent costly downtime.

Calibrating mixing time, speed, and temperature helps achieve consistent results in various industries.

Industry-specific solutions, such as those offered by KARVIL, can further improve the efficiency and reliability of Sigma mixers.

Implementing troubleshooting tips tailored to your specific application ensures that the mixer operates at peak efficiency.

Causes:

Inconsistent mixing quality is one of the most common issues faced by Sigma mixers. This can occur due to improper blade alignment, incorrect mixing speed, or uneven distribution of materials. If the blades are misaligned or the mixer speed is incorrect, the materials may not be thoroughly blended, leading to an uneven mixture. This issue is especially problematic when working with high-viscosity materials like adhesives, creams, or rubber compounds.

Solution:

To address inconsistent mixing, it's essential to ensure that the blades are aligned correctly and that the speed settings are adjusted according to the specific material being processed. Checking the blade angles regularly and ensuring they rotate at the proper speeds will ensure uniform distribution. Furthermore, ensure that the right speed is maintained throughout the entire mixing cycle, as too high or too low a speed can affect the final consistency. Regularly inspecting and adjusting these parameters can help prevent mixing inconsistencies.

| Issue | Cause | Solution |

|---|---|---|

| Inconsistent Blade Alignment | Blades are misaligned | Regular inspection and adjustment of blade angles |

| Incorrect Mixing Speed | Mixer speed set incorrectly for materials | Adjust speed settings based on material viscosity |

| Uneven Distribution of Materials | Improper material loading or mixing time | Ensure proper loading and mixing time consistency |

Regularly monitor and adjust the blade alignment and speed to maintain consistent mixing quality and avoid product variation.

Causes:

Excessive wear on Sigma mixer components is often due to improper lubrication, high-viscosity materials, or overuse without proper maintenance. Over time, the moving parts, such as the agitator blades, drive shafts, and bearings, can wear down, affecting the overall efficiency of the mixer. This issue is especially prevalent when mixing heavy or sticky substances that place significant strain on the machine.

Solution:

To prevent excessive wear, it is essential to perform regular lubrication checks on all moving components, especially the drive shafts and bearings. Following the manufacturer's lubrication schedule can significantly extend the lifespan of these parts. Additionally, using suitable mixing materials and avoiding overloading the mixer will reduce the strain on the components. Regularly replacing worn-out parts and maintaining a lubrication routine will ensure that the mixer operates smoothly.

| Issue | Cause | Solution |

|---|---|---|

| Worn-out Agitator Blades | Lack of lubrication, high-viscosity materials | Regular lubrication and material checks |

| Damaged Bearings | Overuse or lack of proper maintenance | Inspect and replace bearings as part of routine maintenance |

| Strained Drive System | Overloading or incorrect material handling | Follow load limits and use materials as recommended |

Regular lubrication and proper maintenance will help avoid excessive wear and ensure the longevity of your Sigma mixer components.

Causes:

Overheating in Sigma mixers can occur due to malfunctioning cooling systems or incorrect temperature settings. Overheating can cause the motor to fail, leading to costly repairs and downtime. In addition, high temperatures can alter the properties of the materials being mixed, which may affect the final product's quality.

Solution:

To prevent overheating, ensure that the cooling system is properly maintained and calibrated. Regularly check the temperature control settings and make sure they align with the material being mixed. For materials that are heat-sensitive, make sure the mixer is equipped with a cooling system that can maintain the required temperature range throughout the mixing process. If the mixer is overheating due to a cooling system malfunction, replace or repair the faulty components immediately.

| Issue | Cause | Solution |

|---|---|---|

| Overheating due to Cooling System Failure | Cooling system malfunction or blocked pipes | Regularly inspect and maintain the cooling system |

| Incorrect Temperature Settings | Temperature controls not calibrated properly | Regularly calibrate temperature settings |

| Overheating of Motor | High viscosity materials, excessive mixing time | Monitor material temperature and mixing time closely |

Tip: Regularly check the temperature settings and cooling system functionality to prevent overheating and maintain optimal mixing conditions.

Causes:

Motor failure or low torque is often caused by a faulty motor, incorrect voltage supply, or inadequate maintenance of electrical components. A motor that isn’t functioning properly can result in slow or inconsistent mixing speeds, affecting the uniformity of the mixture.

Solution:

To fix motor issues, first, inspect the motor for any signs of damage or wear. Check the voltage supply to ensure that it matches the mixer’s requirements. If the motor is faulty, replace it with a new one. Additionally, maintain the electrical components by regularly checking for loose or frayed wires and ensuring the power supply is consistent.

Causes:

Inconsistent speed control can be caused by problems with the variable speed drive, worn-out components, or faulty connections. This issue can lead to uneven mixing speeds, which may affect the product consistency.

Solution:

Inspect the variable speed drive for any signs of wear and replace any faulty components. Calibrate the speed settings to ensure that the mixer maintains the correct mixing speed throughout the entire cycle. Regular maintenance of the drive system can prevent speed inconsistencies and improve overall mixer performance.

Causes:

Over time, the seals on Sigma mixers may become damaged or misaligned due to wear and tear, exposure to harsh chemicals, or incorrect usage. Damaged seals can lead to material leakage, which affects the mixing process and results in loss of product.

Solution:

Inspect the seals regularly and replace any damaged or misaligned seals promptly. Ensure that the seals are compatible with the materials being mixed to prevent premature wear. Properly maintaining seals will help maintain the integrity of the mixing process.

Causes:

Material leakage often occurs due to faulty seals, discharge gate malfunctions, or improper closure. Leakage can lead to material wastage and contamination of the final product.

Solution:

Ensure that all seals are tightly fitted and check for any gaps or misalignments. Inspect the discharge gate for blockages or mechanical issues that could prevent it from closing properly. Cleaning the discharge gate regularly will ensure smooth operation and prevent leakage.

Key Components to Lubricate:

The drive shaft, bearings, and agitators are essential parts of the Sigma mixer that require regular lubrication. Neglecting lubrication can lead to excessive wear and decreased performance.

Solution:

Follow the manufacturer’s recommendations for lubrication intervals and ensure that the correct lubricants are used. A well-lubricated mixer will operate more efficiently, reducing friction and wear, and extending the lifespan of its components.

Why Blockage Happens:

Blockages in the discharge gate can occur due to dirt, dust, or material buildup, which can obstruct the smooth flow of materials from the mixer.

Solution:

Clean the discharge gate regularly and ensure that it opens and closes fully without obstruction. Regular maintenance will prevent blockages and ensure smooth material discharge.

Impact on Final Product:

Overmixing or undermixing can significantly affect the final product’s quality, causing inconsistencies in texture or composition. Fine-tuning the mixing time and speed is crucial for achieving the desired product consistency.

Solution:

Adjust the mixing time and speed according to the specific material being processed. Experiment with different settings to find the optimal parameters for each application.

Why It’s Critical:

Temperature plays a critical role in the mixing process, particularly when dealing with heat-sensitive materials. Incorrect temperatures can lead to material degradation or improper blending.

Solution:

Monitor the temperature regularly during mixing and ensure the system is calibrated correctly. Implement proper heating or cooling systems to maintain a consistent temperature, especially for sensitive materials.

Key Challenge:

Achieving the right dough consistency is essential for food production, especially for baked goods. Improper mixing can lead to inconsistencies in texture and quality.

Solution:

Ensure that the moisture levels in the dough are properly controlled. Adjust the mixing time according to the type of dough being prepared to ensure uniform hydration and consistency.

Key Challenge:

In pharmaceutical applications, preventing the separation of active ingredients is crucial for product efficacy and safety.

Solution:

Use precise speed and time controls to ensure uniform mixing of active ingredients. Implement dispersants or stabilizers to maintain consistent blending and prevent separation.

Key Challenge:

Agglomeration, or the formation of clumps, is a common issue in the chemical industry when mixing fine powders or high-viscosity materials.

Solution:

Optimize the blade speed and temperature settings to ensure smooth material flow and prevent the formation of clumps. Regular adjustments to the mixer’s parameters can minimize this issue.

Sigma mixers are essential for industries that require precise and consistent mixing of high-viscosity materials. Regular troubleshooting and maintenance, such as proper lubrication, temperature control, and calibration, can help prevent common issues like inconsistent mixing, excessive wear, and overheating. By proactively addressing these issues, you can ensure optimal performance and longevity of your Sigma mixer. Implementing these tips not only improves mixing results but also minimizes downtime, ensuring high product quality.

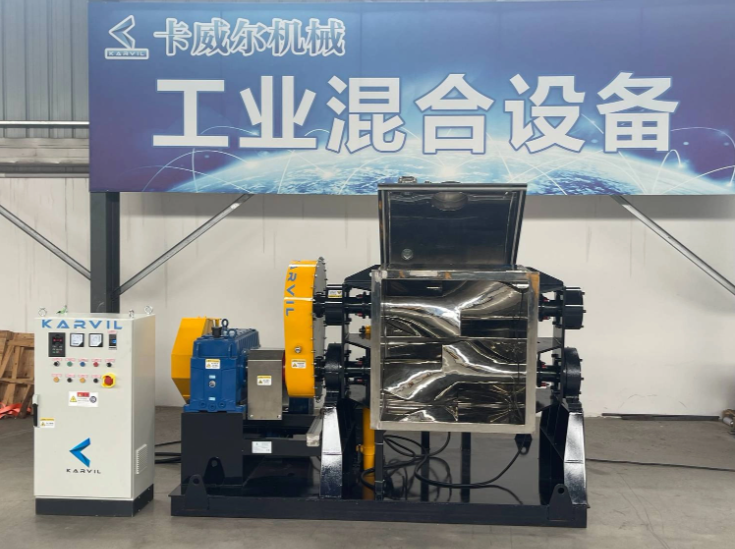

KARVIL offers reliable solutions for maintaining and enhancing the performance of Sigma mixers, ensuring efficiency and durability in demanding industrial applications.

A: A Sigma Mixer is an industrial machine designed for mixing high-viscosity materials. It ensures uniform blending, making it essential in industries like food, pharmaceuticals, and chemicals.

A: To prevent overheating, regularly check the cooling system, calibrate temperature controls, and ensure that the mixer operates within the recommended temperature range.

A: Regular lubrication, checking seals, adjusting mixing speed, and inspecting the discharge gate are key maintenance steps to ensure your Sigma Mixer operates efficiently.

A: Check for blade misalignment or incorrect speed settings. Adjust the blade angles and mixing speed to ensure uniform distribution of materials.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.