WLDH-2000

Customizable Design

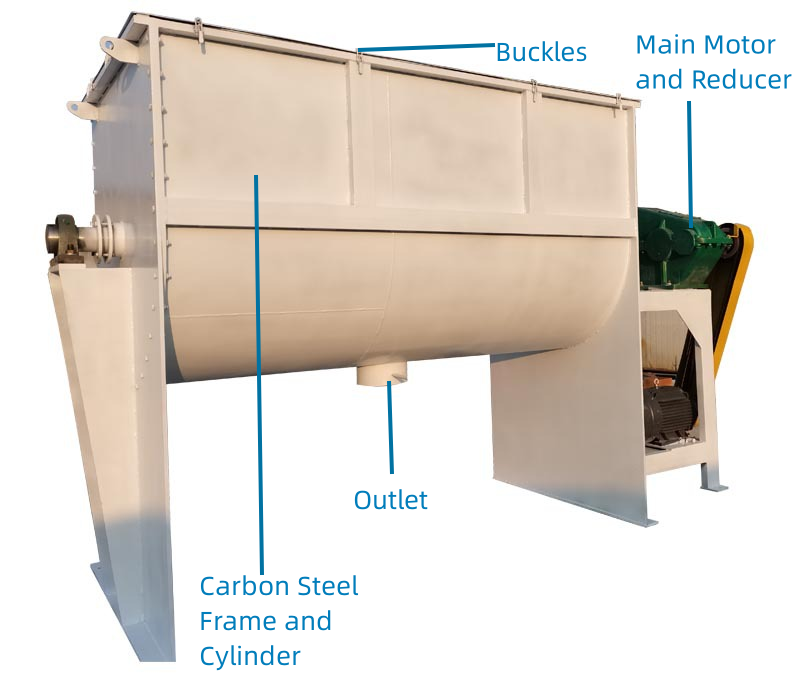

The mixer can be made with all stainless steel or materials contact part with stainless steel or all carbon steel.

Interior Surfaces: Mirror polished.

Discharge: Manual valve or pneumatic valve.

Safety device:Safety grid on the cylinder. Emergency stop device when the lid is open while the safety grip is not on the cylinder

Heating function ( optional): Electric heating with jacket for heating transfer oil; Jacket for steam; Jacket for water circulation.

Cooling function( optional): Jacket for cooling water circulation or equipped together with a chiller.

Vacuum function( optional): it includes vacuum pump, metal hose, buffer tank and vacuum gauge. Vacuum degree can reach-0.096mpa.

Other customized function can be discussed.

Technical Parameters

Applications

Ribbon mixer, also known as a ribbon blender, is a type of industrial mixing machine used for the thorough blending of dry powders, granules, and other solid materials.

Horizontal ribbon mixer is used for powder and powder mixing, powder with a small amount of liquid mixing, suitable for food, building, chemical, agricultural and other industries, such as food powder, dry mortar powder, fertilizer, seeds, spices, coffee powder, etc.

Food Processing Industry

In the food processing industry, the ribbon mixer finds extensive application in various processes such as mixing, blending, and homogenizing of ingredients. With its unique design, the ribbon mixer efficiently combines dry or wet ingredients, ensuring uniform distribution and consistent quality. This versatile mixer is widely used in the production of bakery products, confectioneries, sauces, dressings, and other food items. Its ability to handle a wide range of ingredients, from powders to pastes, makes it an indispensable tool in the food processing industry.

Pharmaceutical Industry

The ribbon mixer plays a crucial role in the pharmaceutical industry, particularly in the formulation of medications and drugs. Its gentle yet thorough mixing action ensures the uniform distribution of active pharmaceutical ingredients (APIs) and excipients, resulting in consistent dosage forms. This application scenario is vital in the production of tablets, capsules, powders, and granules. The ribbon mixer's ability to handle sensitive materials and maintain product integrity makes it an ideal choice for pharmaceutical manufacturers aiming for high-quality and safe medications.

Chemical Industry

The ribbon mixer finds extensive application in the chemical industry for the blending and mixing of various chemicals, powders, and granules. Its robust construction and efficient mixing mechanism enable the homogeneous mixing of different components, ensuring product consistency and quality. This application scenario is particularly relevant in the production of fertilizers, detergents, pigments, plastics, and other chemical compounds. The ribbon mixer's versatility and ability to handle a wide range of chemical compositions make it an indispensable tool for chemical manufacturers.

Construction Industry

In the construction industry, the ribbon mixer is widely used for the preparation of construction materials such as cement, mortar, and plaster. Its efficient mixing action ensures the even distribution of aggregates, binders, and additives, resulting in high-quality and durable construction materials. This application scenario is crucial in various construction projects, including residential, commercial, and infrastructure developments. The ribbon mixer's ability to handle large volumes of materials and its robust design make it an essential equipment for construction companies aiming for efficient and consistent material preparation.

Environmental Industry

The ribbon mixer plays a significant role in the environmental industry, particularly in the treatment and processing of waste materials. Its efficient mixing action facilitates the blending of different waste streams, ensuring proper homogenization and subsequent treatment. This application scenario is vital in waste management facilities, wastewater treatment plants, and recycling centers. The ribbon mixer's ability to handle diverse waste materials, including sludges, solids, and liquids, makes it an invaluable tool for environmental professionals striving for effective waste treatment and resource recovery.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.