| Availability: | |

|---|---|

| Quantity: | |

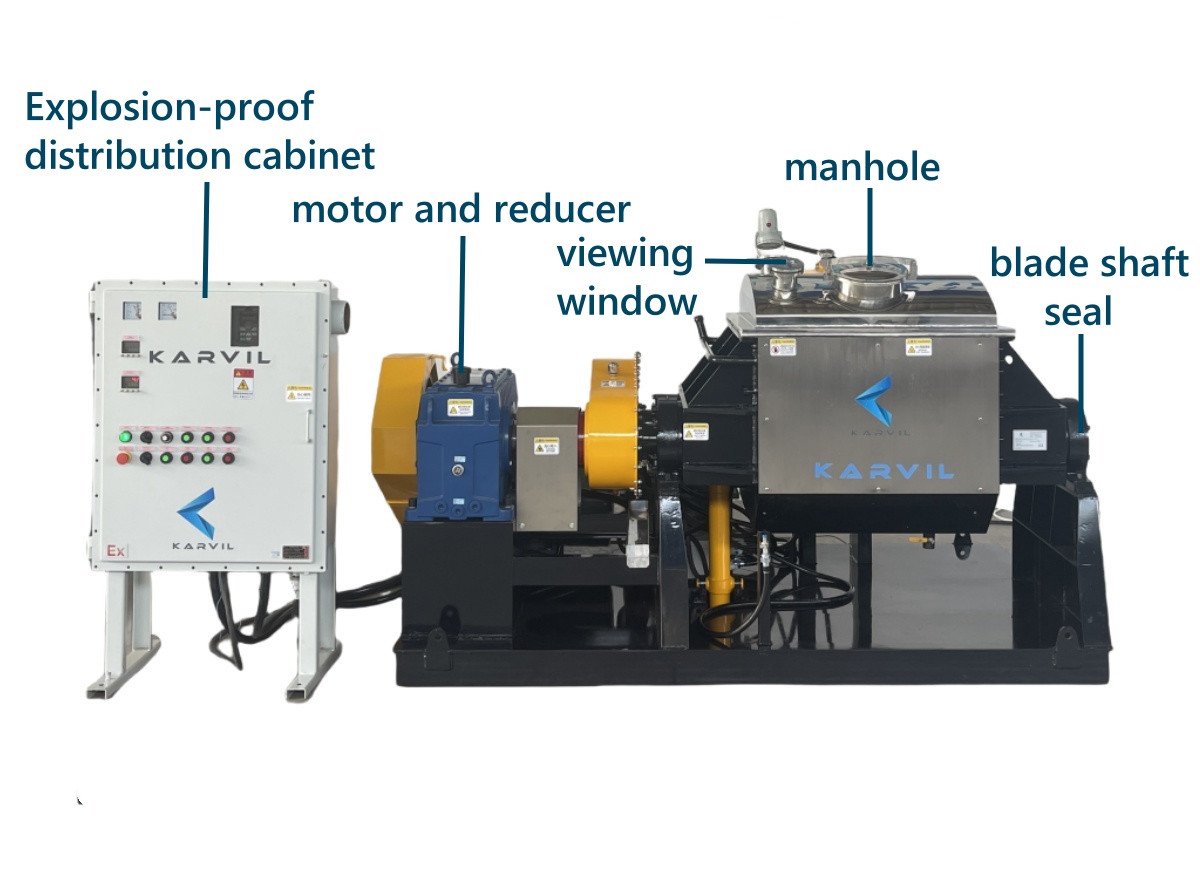

NH-300

Karvil

Customizable Design

Karvil Machinery has designed and manufactured a 150L explosion-proof sigma kneader mixer for a Bulgarian customer, specifically for the safe processing of explosives. Built in accordance with ATEX Zone 21 standards, this kneader ensures maximum safety in handling highly sensitive and hazardous materials.

Full ATEX Zone 21 explosion-proof design for safe operation in hazardous environments

Heavy-duty sigma blades for efficient and uniform mixing of sensitive materials

Hydraulic tilting discharge ensures quick, controlled, and residue-free emptying

Easy maintenance with quick packing seal replacement system

Built with high-grade materials and precision engineering for long-term stabilit

Technical Parameters

Why Choose Us

Experience and Expertise: Karvil Machinery may boast a long-standing reputation in the industry, indicating their experience and expertise in designing and manufacturing machinery for various applications, including mixing and processing equipment.

Customization: Karvil Machinery may offer customization options tailored to specific production requirements. For silicone rubber production, this could involve designing sigma mixers with features such as specialized mixing blades, temperature control systems, or vacuum capabilities to meet the precise needs of the process.

Quality and Reliability: Companies may choose Karvil Machinery for their reputation for producing high-quality, reliable equipment. Quality construction and components in their sigma mixers can ensure consistent performance, durability, and minimal downtime during production.

Technical Support and Service: Karvil Machinery may provide comprehensive technical support and after-sales service, including installation, training, maintenance, and troubleshooting assistance. This level of support can be crucial for ensuring optimal operation and maximizing the lifespan of equipment.

Innovation and Technology: Karvil Machinery may invest in research and development to continually improve their equipment, incorporating the latest innovations and technological advancements. This commitment to innovation could result in sigma mixers that offer enhanced efficiency, precision, and functionality for silicone rubber production.

Cost-effectiveness: While prioritizing quality and reliability, Karvil Machinery may also offer competitive pricing for their equipment, providing excellent value for the investment.

Customer Satisfaction and Reputation: Positive reviews, testimonials, and a strong reputation among existing customers can be indicators of Karvil Machinery's commitment to customer satisfaction and the quality of their products and services.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.