| Availability: | |

|---|---|

| Quantity: | |

NH-100

Karvil

Customizable Design

Engineered to meet the demands of medium-scale industrial production, the NH-100 Silicone Rubber Sigma Kneader Mixer is Karvil’s reliable solution for manufacturers requiring high shear mixing of silicone rubber and other viscous compounds. This model strikes the perfect balance between capacity, efficiency, and customizability, making it ideal for industries such as rubber processing, adhesives, polymer compounding, and chemical manufacturing.

With a total volume of 100 liters and an effective mixing capacity of 30–70 liters per batch, the NH-100 is purpose-built for mid-range production lines. Its Sigma blades rotate at 37 rpm (fast) and 21 rpm (slow), enabling deep penetration and intensive mixing of even the most challenging high-viscosity materials.

Driven by a 5.5–11 kW main motor, this model ensures both torque and precision throughout the mixing cycle. Whether blending raw silicone rubber or compounding additives, the NH-100 guarantees homogeneity and processing consistency across each batch.

The NH-100 stands out for its ideal scale—small enough to fit flexibly in workshop environments, yet powerful enough to support multi-shift industrial production.

The NH-100 offers comprehensive optional features to meet varied material processing needs:

The NH-100 offers flexible heating configurations to suit various process requirements. It supports electric heating with 6 kW power, enabling fast and even temperature rise—ideal for silicone compounds that require heat to activate chemical reactions or adjust viscosity. For more controlled or indirect heating, a steam jacket rated up to 0.3 MPa can be added, providing consistent thermal transfer for temperature-sensitive materials over longer cycles.

To enhance product purity and consistency, the NH-100 can be equipped with a vacuum system capable of reaching -0.096 MPa. This setup includes a vacuum pump, metal hose, buffer tank, and gauge, ensuring stable low-pressure operation. Vacuum mixing is essential for degassing viscous materials like silicone rubber, preventing air entrapment and improving compound density and performance.

For flexible output control, the mixer supports two discharge methods. The tilting cylinder allows quick, clean emptying of the chamber, reducing residue and simplifying batch changes. Alternatively, screw extrusion offers steady, controlled discharge—ideal for processes requiring continuous flow or integration with downstream automation.

This flexibility allows operators to tailor the NH-100 for a wide range of applications—from batch-based silicone rubber formulations to continuous compound delivery into downstream equipment.

To ensure long-term durability and compatibility with chemically aggressive or high-purity materials, all product-contact components in the NH-100 can be customized using SS304 or SS316 stainless steel with mirror polish. The frame and non-contact components are fabricated from carbon steel and finished with automotive-grade industrial paint for maximum resistance to wear and environmental exposure.

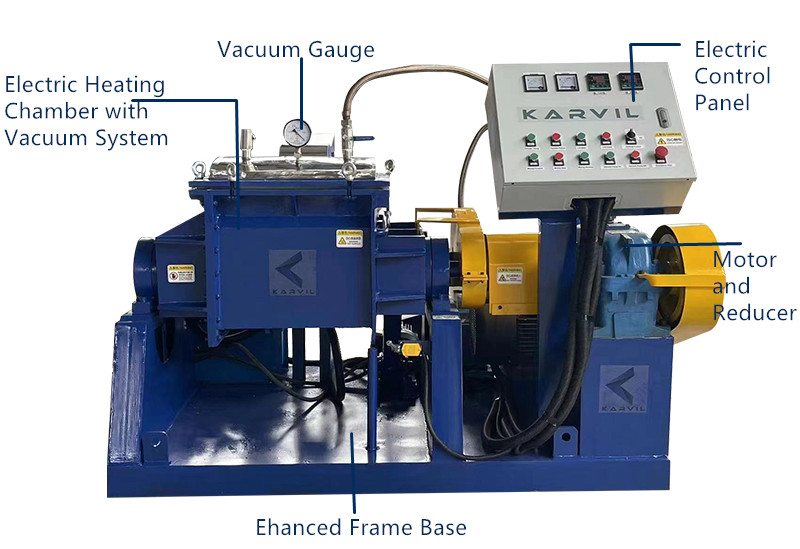

A user-friendly independent control panel comes equipped with:

Schneider electronic components

Function-specific switches

Voltage and current displays

Overload and circuit breaker protection

Inverter control for blade speed adjustment

These features not only support efficient operation but also align with growing demands for automated kneader mixers in smart factories and advanced material labs.

The NH-100 model is tailored for users seeking a medium-capacity kneader mixer with advanced configurability. Its optimized size, energy-efficient design, and support for auxiliary systems (vacuum, heating, cooling) reflect the current industry shift toward process flexibility, reduced downtime, and cleaner production environments.

Common applications include:

Silicone rubber mixing with fillers or pigments

Adhesive base compound blending

Viscous sealant or chemical paste formulation

Food-grade or pharmaceutical elastomeric processing (with stainless steel customization)

With a moderate footprint, the NH-100 easily integrates into semi-automated or fully automated production lines, providing maximum return on investment for mid-sized manufacturers.

Looking for a reliable, energy-efficient, and configurable Sigma Kneader Mixer? Contact Karvil today to discuss your production needs and discover how the NH-100 model can enhance your material processing workflow. Our technical team will assist you with configuration options, performance insights, and after-sales support to ensure your investment delivers lasting value.

Technical Parameters

Applications

Silicone Rubber

A kneader, such as a sigma mixer, plays a crucial role in the production of silicone rubber. Silicone rubber is a versatile material known for its high heat resistance, excellent electrical insulation properties, and flexibility. The manufacturing process involves mixing various ingredients to achieve the desired properties in the final product.

Here's how a kneader, like a sigma mixer, contributes to silicone rubber production:

Homogeneous Mixing: Silicone rubber production requires blending various ingredients such as silicone polymers, fillers, plasticizers, curing agents, and additives. A sigma mixer provides efficient and thorough mixing, ensuring uniform distribution of these components throughout the mixture. This homogeneous blending is essential for achieving consistent product quality and properties.

Dispersion of Fillers: Fillers, such as silica or carbon black, are often added to silicone rubber to enhance its mechanical properties, such as tensile strength and abrasion resistance. The kneading action of the sigma mixer helps disperse these fillers evenly within the silicone matrix, preventing agglomeration and ensuring that they are uniformly distributed throughout the mixture.

Temperature Control: Some silicone rubber formulations require precise temperature control during mixing to facilitate the incorporation of curing agents or to prevent premature curing. Sigma mixers can be equipped with heating or cooling systems to maintain the desired temperature throughout the mixing process, allowing for optimal processing conditions.

Degassing: Air bubbles can affect the quality and performance of silicone rubber products. Sigma mixers often feature vacuum capabilities to remove trapped air and gases from the mixture during mixing. This degassing process helps produce silicone rubber with improved mechanical properties and reduced porosity.

Consistency and Efficiency: Kneaders like sigma mixers offer high throughput rates and consistent mixing performance, allowing for efficient production of silicone rubber compounds. The robust design of sigma mixers enables continuous operation, minimizing downtime and ensuring a steady supply of quality silicone rubber compounds.

Overall, the kneading action, temperature control, and degassing capabilities of sigma mixers make them indispensable equipment in the manufacturing process of silicone rubber, contributing to the production of high-quality, performance-driven materials used in various industries, including automotive, electronics, healthcare, and construction.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.