Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

Mixing powders sounds simple, but it’s not. If the mix isn’t even, your product fails. That’s why many manufacturers choose a horizontal ribbon blender. It’s fast, reliable, and easy to use.

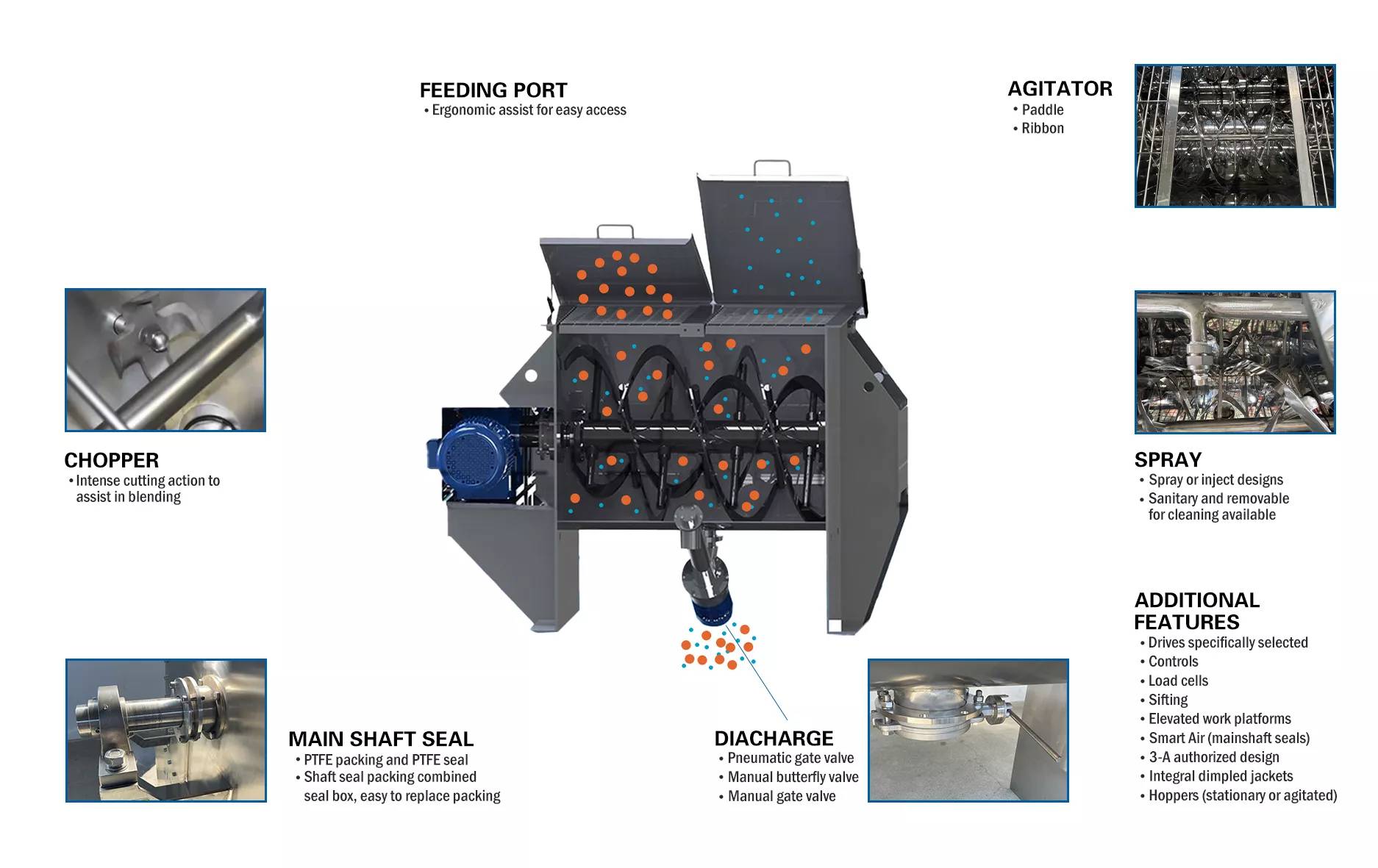

A ribbon blender has a U-shaped tank and a set of spiraled blades inside. The blades move powders in two directions—left and right—at the same time. This helps to mix everything evenly. No clumps. No dead corners.

Even Mixing

The double-layer ribbon makes sure each batch is mixed well from end to end.

Works with Many Powders

It’s great for cocoa, matcha, sugar, protein powder, chemicals, and more.

Easy to Clean

You can open the lid and clean inside easily. No tools needed. Some machines have polished surfaces and quick-release parts.

Easy Feeding

Pair the blender with a screw conveyor or feeder. It makes loading faster and safer.

Saves Energy

The motor is powerful but not wasteful. You get more output with less power.

Food industry – spices, coffee powder, sweeteners

Chemical industry – paints, resins, pigments

Pharma industry – vitamins, dry medicine, excipients

Agriculture – animal feed, crop powder

Karvil has made mixers for over 20 years. We serve customers in more than 50 countries. Our ribbon mixers come in many sizes—from 100L to 5000L. We also build custom systems with feeders, control panels, or even vacuum options. All machines are made from strong materials like stainless steel 304 or 316L.

Want a mixer that fits your needs? Just ask us.

frank@karvil.com

www,sigmazs.com

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.