Capacity: 2700 Liters

Main Motor: 110 kW (6-pole) WEG Brand with UL Certification

Blade Type: Dual Sigma Blades

Blade Material: Wear-resistant Mn16 Steel (10mm thick coating on blades)

Heating Method: Electric Heated Jacket (Thermal Oil as medium)

Discharge Method: Screw Extrusion

Vacuum System: Included (Vacuum Pump, Buffer Tank, Metal Hoses)

| Availability: | |

|---|---|

| Quantity: | |

NH-2700

Customizable Design

The material contact part can be SS304, SS316 with mirror polished or carbon steel. The rest part can also be stainless steel and mostly adopt carbon steel with automotive grade industrial paint

Sigma blades speed can be adjustable with inverter control; one is fast and another is slow.

Discharge method can hydraulic tilting discharging or screw extrusion discharging or both of them.

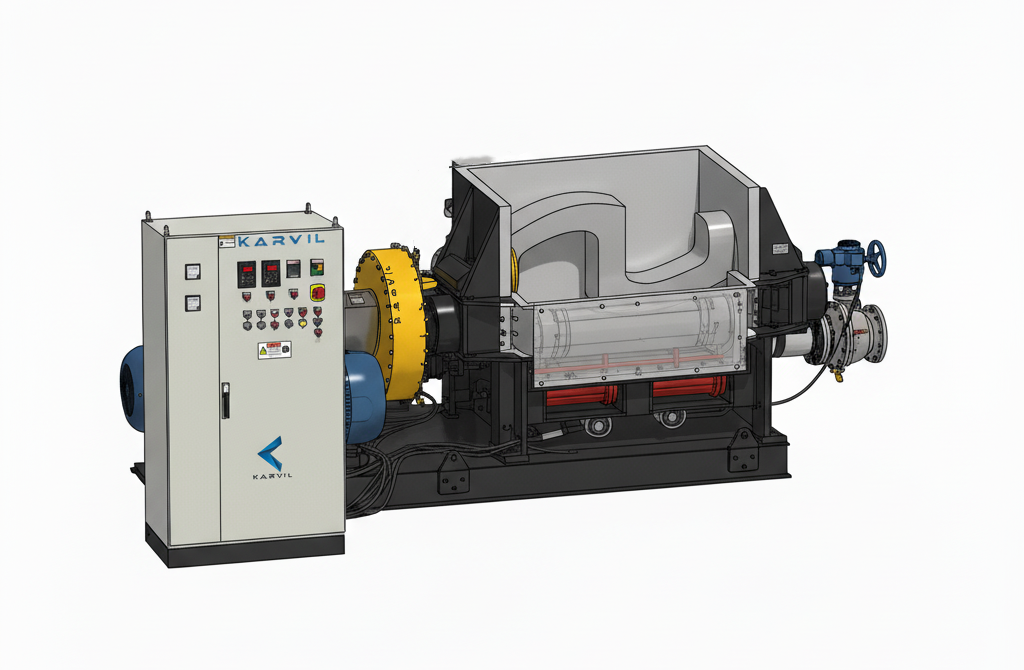

Independent Control Panel: Function control,Schneider electronic components,Circuit breaker protection,Voltage & current showed and etc.

Vacuum function( optional): it includes vacuum pump, metal hose, buffer tank and vacuum gauge. Vacuum degree can reach-0.096mpa

Heating function ( optional): Electric heating with far ultrared heaters or with jacket for heating transfer oil; Jacket for steam; Jacket for water circulation.

Cooling function( optional): Jacket for cooling water circulation or equipped together with a chiller.

Other customized function can be discussed.

KARVIL 2700L Electric Heated Vacuum Screw Extrusion Sigma Blade Kneader

Introducing the KARVIL 2700L Electric Heated Vacuum Screw Extrusion Kneader – a state-of-the-art mixing solution specifically designed for the most challenging industrial applications. This robust machine, successfully deployed for our esteemed client in the USA, is expertly engineered to efficiently process crushed asphalt shingles, delivering unparalleled consistency, quality, and operational efficiency.

Unmatched Performance for Asphalt Shingle Recycling:

The KARVIL 2700L kneader is not just a mixer; it's a dedicated workhorse optimized for the demanding task of recycling and reclaiming asphalt shingles. Its advanced features ensure that even the toughest, most viscous materials are thoroughly blended and processed for reuse, contributing to sustainable practices and resource conservation.

Key Technical Specifications & Benefits:

Powerful & Reliable Drive System:

Main Motor: Equipped with a formidable 110 kW - 6-pole WEG (Wegener Electro Motors GmbH) motor, renowned globally for its superior efficiency, durability, and reliability. This motor comes with UL certification, guaranteeing compliance with stringent North American safety and quality standards, providing peace of mind for our US customers.

Advanced Mixing Element – Dual Sigma Blades:

Blade Design: Features dual Sigma (Σ) type mixing blades, specifically engineered for high-shear, intensive mixing of extremely viscous materials. This unique design ensures maximum material contact, superior kneading action, and homogenous blending, even with dense and cohesive substances like asphalt shingles.

Wear-Resistant Construction: The exterior of the mixing blades is fortified with a 10mm thick Mn16 wear-resistant steel plate. This high-manganese steel provides exceptional resistance to abrasion and impact, significantly extending the lifespan of the blades and ensuring consistent performance when processing abrasive materials like crushed asphalt.

Precision Temperature Control – Electric Heated Jacket:

Heating Method: The mixing trough is fitted with a robust heating jacket, designed for uniform temperature application.

Heat Transfer Medium: Utilizes thermal oil as the heat transfer medium, enabling precise and stable temperature control crucial for softening and maintaining the optimal viscosity of asphalt-based materials. This ensures efficient plasticization and blending.

Efficient Vacuum System:

Complete Vacuum Unit: Features a comprehensive vacuum system including a powerful vacuum pump, a dedicated buffer tank, and durable metal flexible hoses. This system effectively removes air, moisture, and volatile components from the material during mixing, preventing oxidation, improving material density, and enhancing product quality. Essential for producing high-grade asphalt compounds.

Controlled Screw Extrusion Discharge:

Discharge Method: Incorporates a highly efficient screw extrusion discharge mechanism. This allows for continuous, controlled, and complete emptying of the mixing chamber, minimizing material residue and enabling seamless integration with subsequent processing stages. It drastically reduces manual labor and improves overall process efficiency.

Technical Parameters

FAQ

Q1: Why is Tungsten Carbide coating necessary for this machine?A: Tungsten Carbide is applied to the mixing blades and contact surfaces to provide extreme wear resistance. It is essential when processing highly abrasive materials like Alumina and Bauxite, which quickly degrade standard stainless steel, ensuring a dramatically longer lifespan and preventing metal contamination.

Q2: What is the primary function of the vacuum system?A: The high-vacuum system (up to -0.095 MPa) serves to degas the material during mixing. It removes trapped air bubbles, moisture, and volatile components, which is critical for achieving high density and purity in end products like advanced ceramics and high-performance powders.

Q3: How does the screw discharge mechanism benefit production?A: For high-viscosity, non-flowing pastes, conventional tilting can be difficult and leave residue. The screw discharge mechanism actively extrudes the finished product quickly and completely, ensuring faster batch turnover and virtually zero material waste.

Q4: Is the 50L capacity suitable for R&D or production?A: The 50-liter working capacity is versatile. It is ideally suited for R&D departments to finalize formulas and scale-up trials, as well as for small to mid-batch specialized production where material volume is high-cost or limited.

Q5: Can this machine handle materials that generate heat during mixing?A: Yes. The machine is equipped with a Cooling Jacket around the mixing chamber. This allows for the circulation of cold water or thermal fluid to precisely manage and dissipate the heat generated by the intense shear mixing, ensuring optimal process temperatures.

Q6: Can the machine be customized beyond the Tungsten Carbide coating?A: Absolutely. While the Tungsten Carbide is a core feature for this specific application, we offer customization in several areas, including motor power, temperature control range (heating and cooling options), and PLC automation levels, to perfectly fit your unique process requirements.

Q7: What industries commonly use this specific configuration?A: This high-end configuration is mainly used in Advanced Materials, specifically in the production of:

High-performance ceramics (Alumina, Zirconia)

Refractory and abrasive compounds

Specialized powder metallurgy (MIM)

High-viscosity chemical pastes.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.