Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

We are delighted to share a success case for Greek client, a bakery company that required extensive non-standard customization.

In early 2023, the client reached out to Karvil while searching for a reliable food-industrial mixer supplier. They had specific ideas in mind but were unsure if their unique requirements could be met.

In order to close this deal, we analyzed their needs—including custom capacity, specialized mixing functions, and food-grade material adaptations—and delivered a customized solution that exceeded expectations.

This case demonstrates Karvil’s expertise in flexible engineering and customer-driven innovation, proving that even highly specialized demands can be achieved.

1.Mixing Capacity & Design

Working capacity: 250 liters, suitable for batch processing of flour, calcium propionate, sugar, salt, etc.

Horizontal screw ribbon design ensures effective mixing.

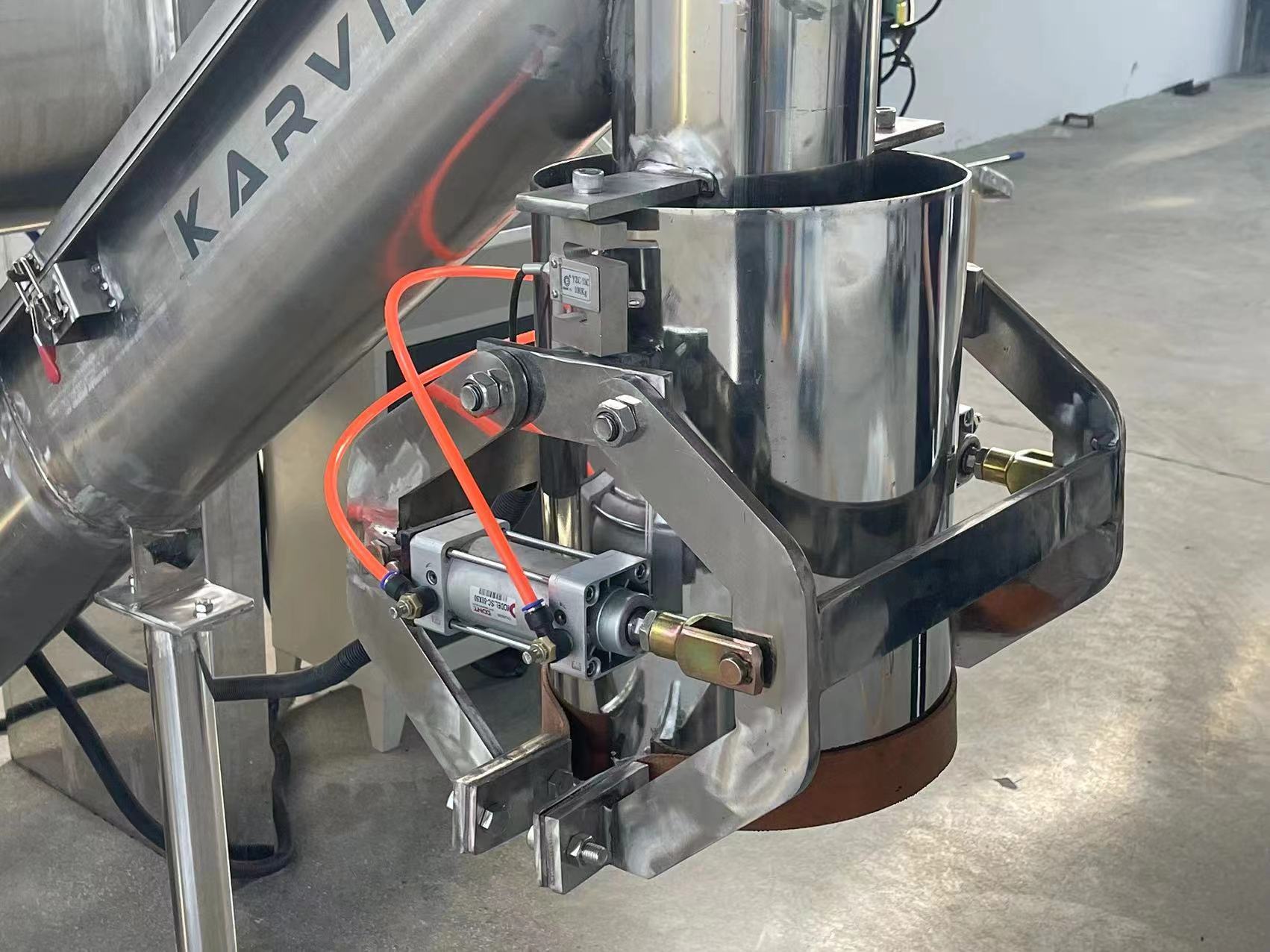

Equipped conveyor at the outlet port for controlled material discharge.

PLC-controlled weighing system guarantees precise batch output weight.

Clamping bag device at the conveyor outlet enables clean, spill-free packaging.

Non-stick interior surface (client’s requirement to minimize material sticking to the wall).

Two pre-installed connection ports for the client’s pneumatic cleaning system (e.g., air blower or vacuum).

Openable top cover for quick maintenance and thorough cleaning.

Strictly manufactured to meet the 250L working volume requirement for consistent batch processing

Integrated PLC with HMI touchscreen interface for precise discharge weight control

Programmable logic for accurate batch management

Factory-equipped clamping bag device for clean material discharge

Minimizes product loss and maintains hygienic operation

Specialized Teflon scrapers installed on ribbon blades

Effectively reduces material buildup on mixing chamber walls

U-shaped screw conveyor design for efficient material transfer

Manually operated open/close lid mechanism for:

Easy cleaning access

Convenient maintenance

Quick visual inspection

The advantages of solutions :

Exact batch control – Guarantees each batch meets the precise 250L specification, minimizing waste.

Consistent results – Uniform mixing ensures product quality remains consistent from one batch to the next.

Accurate discharge control – PLC ensures precise weight measurement for each batch.

Intuitive interface – HMI touchscreen simplifies programming and monitoring.

Reduced human error – Automation enhances reliability compared to manual weighing process.

Minimized spillage – The sealed discharge mechanism prevents product loss and dust contamination.

Hygienic packaging – Ensures compliance with food-grade standards (such as for flour or additives).

Faster Bagging – Improved Efficiency

The new setup speeds up the bagging process and keeps everything running smoothly, which means higher overall productivity.

No sticking issues – Teflon scrapers reduce product buildup on surfaces.

Save raw materials – More product is discharged, leaving less residue.

Simple cleaning – With less material sticking, cleaning and upkeep take less time.

No clogging – The U-shaped design ensures a consistent material flow.

Quick cleaning access – A manual lid makes it easy to:

Clean efficiently and meet food safety standards.

Carry out inspections without using tools.

Cut down maintenance time and avoid long downtimes.

Project Results

This project shows how Karvil Machinery focuses on solving real customer challenges. By understanding what the bakery needed, we provided a practical solution that:

Increased batch accuracy and consistency

Improved production speed and efficiency.

Lowered costs by reducing waste and downtime.

For the bakery, this meant faster turnaround times, cleaner operations, and less time spent on cleaning and maintenance—key factors for staying competitive.

Conclusion

Karvil Machinery designs and builds customized mixer and conceyors to help customers boost efficency mixers and conveyors tailored to each client’s space and capacity requirements. Our goal is simple: to help customers boost efficiency, reduce waste, and keep their production lines running smoothly.

We don’t just build equipment—we create solutions that fit your business. If you’re looking for a reliable partner to optimize your production,get in touch with karvil machinery today .

frank@karvil.com

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.