Views: 0 Author: Site Editor Publish Time: 2025-10-07 Origin: Site

About the Client

In 2025, Karvil Machinery was honored to cooperate with a Greek company well known for its expertise in high-performance silicone and polymer products. This client designs, produces, and supplies tubes and profiles made from silicone, TPE, and advanced polymers to industries such as healthcare, food, beverage, and dairy.

With strict requirements for hygiene, durability, and precision, they needed a sigma kneader that could mix silicone rubber compounds. Since silicone rubber does not require heating or vacuum treatment, they requested a machine with reliable cooling functions only. From the very beginning, it was clear that this was not a simple equipment sale—it was a technical cooperation where every detail mattered.

Client’s Technical Questions and Our Answer

1. Material Viscosity

Client: “Our materials have Mooney viscosity of 60–70. Can your kneader handle this?”

Karvil: “Yes. Our 100L sigma mixer is designed for high torque mixing. The gearbox and blades can handle high-viscosity silicone without issue.””

2. Single vs Multiple Equipment

Client: “Do we need any extra equipment besides the kneader?”

Karvil: “No. A single sigma mixer is enough to complete the process. No additional mixers or external devices are necessary.”

3. Mixing Time per Batch

Client: “How long does one batch take to mix?”

Karvil: “The exact time depends on your formula and target properties. It is not possible to give a fixed number, but we can provide references from similar silicone mixing projects.”

4. Cleaning

Client: “How do we clean the chamber after mixing?”

Karvil: “Silicone rubber typically comes out as one block. After discharge, only a small spatula is needed to scrape off the remaining residue. The chamber’s smooth stainless-steel surface makes cleaning quick and easy.”

5. Custom Die at Discharge

Client: “Can we attach our own mold at the extrusion outlet?”

Karvil: “Yes. The outlet size is DN100, and you can add your own die or request us to design one. This makes it possible to form the silicone into controlled shapes directly during discharge.””

6. Noise Level

Client: “How many decibels during operation?”

Karvil: “The machine operates at less than 90 dB. If required, we can also provide a soundproof cover to further reduce noise.”

7. Cooling Performance

Client: “Do you have any efficient cooling design?”

Karvil: “Yes. We offer a new system where cooling water circulates not only in the jacket, but also in the hollow blades and screw barrel. This triple cooling structure improves heat exchange efficiency significantly.”

The customer showed strong interest in this design and asked:

1. “What is the geometry of the hollow channels?”

2. “Will reducing material thickness weaken the blades?”

We provided detailed drawings and explained:

1. The internal channels are 1 mm thick.

2. To ensure durability, the outer surfaces are reinforced with 5 mm stainless steel (SS304).

3. This ensures both efficient cooling and reliable mechanical strength.

The client was satisfied with our explanation and considered the solution both innovative and safe.

Description of the 100L Sigma Mixer

The machine chosen for this project was a 100L sigma mixer with screw extrusion discharge, specifically designed for high-viscosity materials like silicone rubber.

1. Mixing Chamber:

Constructed from food-grade SS304 stainless steel, polished for easy cleaning and long-term durability. The chamber includes a jacket for cold-water circulation to control material temperature.

2. Sigma Blades:

Two sigma blades rotate with strong torque. Each blade is hollow inside, allowing cooling water to pass through, which helps absorb heat generated by friction during mixing.

3. Screw Extrusion System:

The Sigma mixer is equipped with a horizontal screw extrusion device connected to the bottom. After mixing, material can be discharged directly and evenly. The outlet size is DN100, which allows attachment of different dies for shaping the final output.

4. Drive System:

A powerful gearbox coupled with an energy-efficient motor ensures stable torque and reliable performance. Speed can be adjusted through an inverter to control the mixing process.

5. Control cabinet:

The electrical cabinet provides simple operation with clear start/stop functions, blade direction control, and screw discharge control. Noise level is below 90 dB, ensuring safe working conditions.

6. Cooling Design:

The most important feature is the multi-level cooling system:

A. Water jacket around the chamber

B. Cooling channels inside the sigma blades

C. Cooling inside the screw barrel

This design allows heat to dissipate quickly, keeping silicone rubber at stable processing temperatures.

Production, Photos, and Testing

Once the machine was manufactured, we followed our standard quality control process:

1. Photo Documentation:

We took detailed photos of every part of the mixer—including chamber, blades, gearbox, screw extrusion system, and control panel. These were sent to the client so they could visually confirm every detail before shipment.

2. Trial Operation Video:

A full test run was recorded. The video showed the blades rotating forward and reverse, screw discharge operation, and the cooling system in function. This gave the client confidence that the machine was tested and fully functional before leaving our factory.

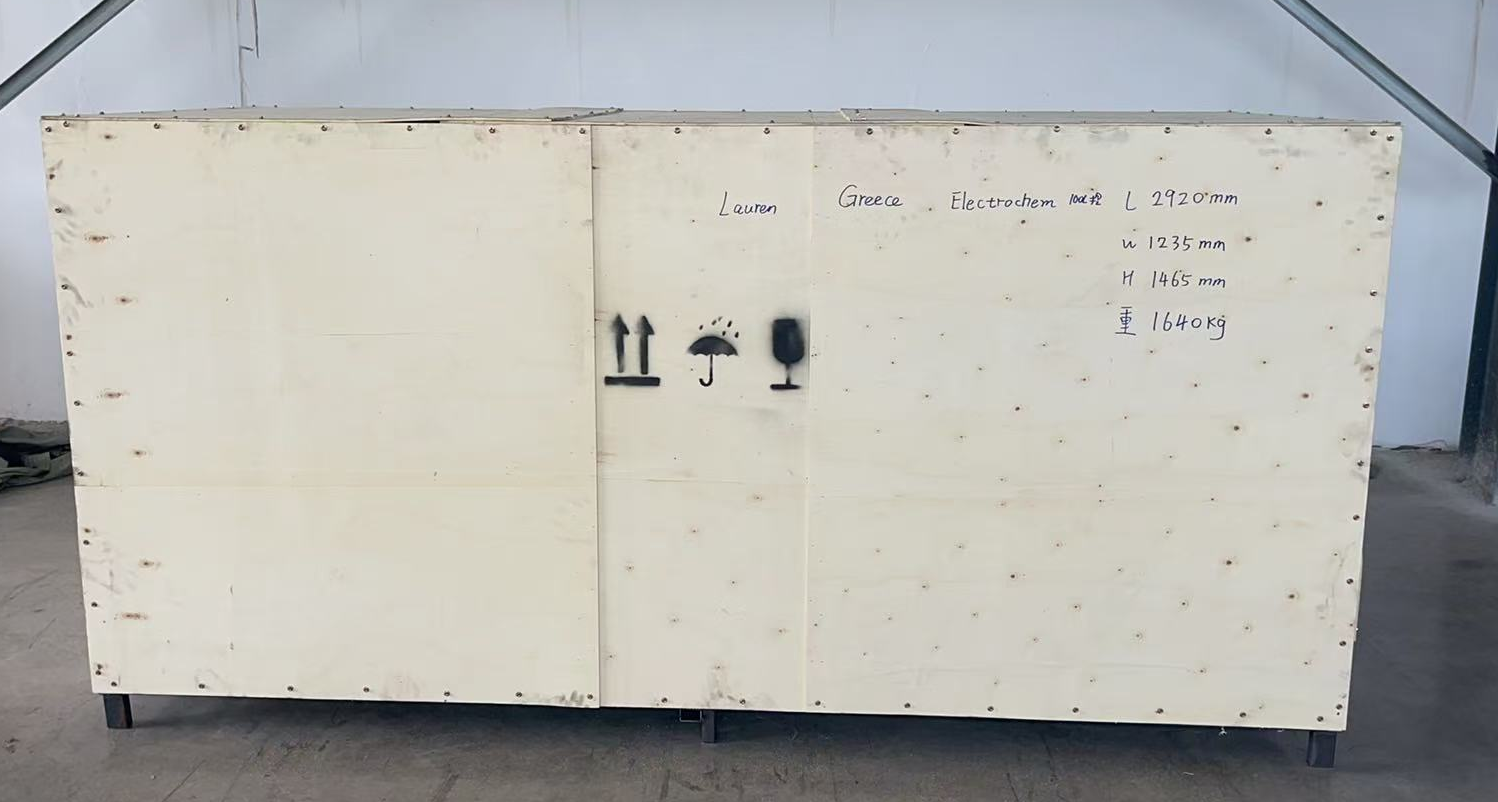

3. Packaging:

The mixer was packed in a strong fumigation-free wooden case with protective supports to prevent any transport damage.

4. Documents:

We provided the client with a commercial invoice, packing list, certificate of origin, CE certificate, and HS code references. This ensured smooth customs clearance in Greece.

Order Confirmation and Customer Satisfaction

After reviewing the photos, trial videos, and technical documents, the client confirmed the order. They appreciated our honest communication, detailed documentation, and careful testing before shipment.

This project proved that even a 100L capacity mixer can meet the advanced requirements of global leaders in silicone and polymer processing. The customer emphasized that the cooling design and ability to connect their own molds were decisive advantages.

Why the Client Chose Karvil

A. Strong torque performance suitable for silicone with Mooney viscosity 60–70

B. Advanced multi-layer cooling design with proven success in similar projects

C. Easy cleaning and stainless-steel construction for long service life

D. Flexible customization at the extrusion outlet

E. Transparent technical support with drawings, videos, and trial reports

F. Reliable service including documentation and packaging for safe international delivery

Looking Forward

This successful project with the Greek client highlights Karvil Machinery’s ability to adapt technology for high-performance polymer industries. By focusing on cooling efficiency, process integration, and operator convenience, we delivered more than just a machine—we delivered a solution.

The Greek customer was highly satisfied with the cooperation and has already expressed interest in future projects with larger capacities. With strong technical communication, customized engineering, and reliable after-sales support, Karvil Machinery continues to build long-term partnerships across Europe and beyond.

At Karvil, we believe earning trust starts with doing the basics right: honest answers, reliable machines, and ongoing service. This 100L sigma mixer project in Greece is another proof that when technology and service come together, partnerships last.

frank@karvil.com

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.