Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Is your mixing process failing under extreme pressure and sticky loads? High-viscosity materials strain systems and ruin consistency fast. A dedicated Sigma Mixer keeps flow stable and product quality intact. This guide explores how the right Sigma Mixer solves dense mixing challenges. We clarify performance needs, design choices, and cost impact. You will see what drives reliable high-viscosity production success. In this article, you will learn how to choose the best Sigma Mixer. We cover blade design, torque balance, and smart capacity planning. You will gain clear steps for confident equipment decisions.

Selecting the right Sigma Mixer depends on viscosity, torque, and blade design alignment.

Proper capacity planning prevents overload and preserves batch consistency.

Hygienic construction ensures regulatory compliance and product safety.

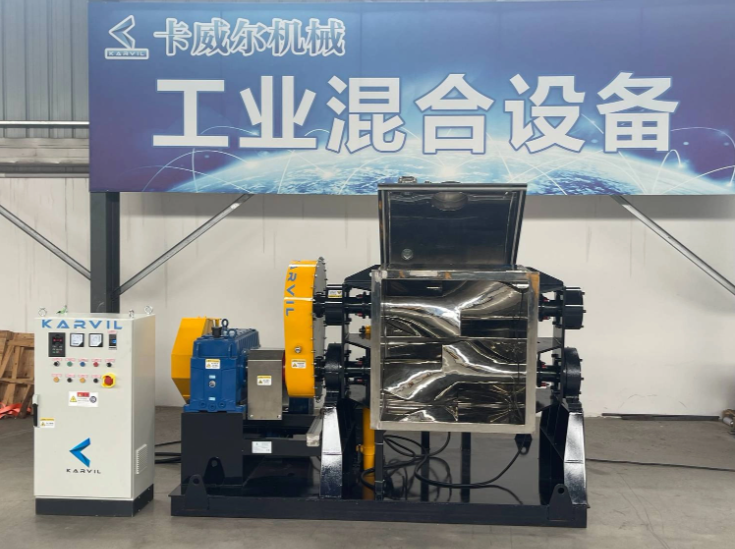

KARVIL Sigma Mixer systems provide durable, energy-efficient solutions for demanding industries.

Correct design decisions reduce downtime and improve overall ROI.

High viscosity describes materials that resist motion under applied shear. They tend to behave like semi-solids and require prolonged force for deformation. These materials often exceed 100,000 cP (needs verification). They generate friction heat during processing. A Sigma Mixer handles such conditions by distributing force evenly. It also keeps temperature rise within safe limits.

Rheology determines flow resistance and shear response. It influences blade engagement and mixing time. Poor rheology matching leads to incomplete dispersion. Proper testing reveals optimal blade geometry needs. It also guides motor load requirements. Engineers rely on rheology to fine-tune Sigma Mixer architecture.

Shear force breaks material lumps and disperses particles. Kneading folds and compresses layers methodically. Torque sustains steady blade rotation under resistance. Balanced force application prevents mechanical failure. It also stabilizes mixing quality. Correct calibration protects product integrity.

Food: dough, cacao paste, caramel

Pharma: gels, medicated ointments

Chemicals: adhesives, rubber compounds

Battery: slurry electrodes

| Industry | Application | Required Mixer Feature |

|---|---|---|

| Food | Dough blending | Gentle kneading |

| Chemical | Sealants | High torque |

| Pharma | Creams | Hygienic structure |

Rheology shifts during mixing cycles.

Tangential blades offer intense shear and robust kneading. They suit materials with extreme resistance. Overlapping blades apply smoother pressure and controlled folding. They work well for creams and semi-soft pastes. Blade type influences torque demand and cycle duration. A precise match ensures stable mixing.

| Blade Type | Ideal Use | Shear Level |

|---|---|---|

| Tangential | Rubber, sealants | High |

| Overlapping | Ointments | Medium |

Motor output affects performance longevity. High torque is essential for viscous load stability. Tip speed determines friction and heat formation. Proper balance prevents overheating. It also preserves material characteristics. KARVIL Sigma Mixers apply optimized torque motors for precision output.

A rigid structure absorbs vibration stress. Reinforced frames maintain operational balance. Strong housing lengthens service life. It reduces structural deformation. KARVIL equipment uses heavy-duty frames for durability.

Controlled volume ensures optimal blade contact. Overfilling restricts material flow. Underfilling causes slippage zones. The ideal range maintains pressure equilibrium. It also avoids equipment overload.

Load capacity must match resistance type. Should support peak torque durations. Testing prevents abrupt stall points. KARVIL offers tailored load engineering.

Sensitive polymers degrade under heat stress. Proper heat control preserves formulation. Jacketed troughs reduce friction build-up. It also enhances product consistency. Request torque curves before purchase.

W-shaped designs guide even material flow. They support blade trajectory and surface contact. It minimizes retention zones. It enhances kneading efficiency. This structure improves circulation control, reduces material buildup along chamber walls, and ensures consistent pressure distribution, helping operators achieve smoother blending, higher productivity, and more dependable processing results.

Gear systems boost longevity. Couplings ease load transition shock. Heavy-duty motors tolerate high stress loads. KARVIL mixers integrate robust drive assemblies for reliability. These reinforced components improve operational stability, reduce vibration impact, and support continuous performance, allowing longer service intervals and dependable high-viscosity production efficiency.

Jackets allow heating or cooling fluid cycles. They stabilize processing temperature. It avoids overheating incidents. It secures sensitive batches. This temperature control protects formulations from degradation, maintains consistent viscosity, and improves overall product uniformity, especially during extended mixing cycles and precision industrial testing operations.

Low speed reduces air entrapment. High torque powers dense loads. It optimizes blend quality. It ensures inside uniformity. Stable speed improves batch consistency. This balanced operation promotes smoother texture, limits foam formation, supports accurate ingredient distribution, and enhances overall process reliability for demanding high-viscosity production tasks.

Nominal ratings differ from effective output. Real volume must accommodate stress margin. It prevents cycle disruption. It promotes stable performance. Proper capacity planning also reduces motor strain, improves torque consistency, and supports smoother batch transitions, helping production teams maintain reliable output quality and avoid unexpected shutdowns during high-viscosity mixing operations.

Gradual scaling ensures predictable output. Monitoring energy use avoids overload failure. KARVIL provides scalable system options for growth. This approach improves process flexibility, controls operational risks, and allows manufacturers to expand production capacity without sacrificing efficiency, stability, or long-term equipment reliability under increasing workload demands.

Maintain ideal fill level

Inspect blade clearance

Adjust cycle duration

Avoid maximum fill during pilot runs.

Stainless ensures corrosion resistance. It suits food-grade production. Carbon steel costs less but requires coating protection. KARVIL provides both options with certified quality. These material choices support long-term durability, improve hygiene standards, and help manufacturers control costs while maintaining structural strength and regulatory compliance across demanding high-viscosity processing environments and continuous production operations.

GMP compliance ensures sanitation safety. Smooth surfaces enhance cleaning. It passes inspection audits. This design approach reduces contamination risks, simplifies routine maintenance, and supports reliable process validation, allowing facilities to meet strict industry standards while protecting product integrity and maintaining consistent performance in sensitive production areas.

Chemicals damage untreated surfaces. Protective alloy coatings prevent degradation. KARVIL systems apply advanced corrosion shields. These protective measures extend equipment lifespan, reduce repair frequency, and enhance operational safety while ensuring stable performance under aggressive chemical exposure and harsh industrial processing conditions over extended production cycles.

Detachable lids reduce downtime. Polished internals improve hygiene. It supports quick wash cycles.

| Construction Type | Application | Durability |

|---|---|---|

| 316L Stainless | Pharma | High |

| Carbon Steel | Chemicals | Moderate |

Compliance improves buyer trust.

Hydraulic tilt ensures complete transfer. It handles thick batches. It minimizes residual waste. KARVIL designs smooth hydraulic discharge mechanisms. This system improves unloading speed, reduces manual intervention, and maintains cleaner work areas while supporting consistent batch removal, safer operation, and efficient material flow control during high-load production cycles.

Screw systems allow steady output flow. They suit automated production lines. It shortens handling time. This controlled discharge supports continuous processing, limits product spillage, and enhances workflow coordination, enabling operators to achieve stable throughput, reduced labor effort, and improved production accuracy across demanding manufacturing environments.

Valve output works well for semi-fluid compounds. It reduces exposure and contamination risk. Choose discharge type per floor layout. Proper selection improves hygiene control, simplifies cleaning procedures, and supports safer material handling while enhancing layout efficiency and reducing cross-contamination issues in regulated production zones.

Cheaper models increase energy loss. Premium equipment assures longevity. KARVIL Sigma Mixers deliver meaningful cost savings across lifespan. They reduce unexpected downtime, support stable output, and lower maintenance frequency, helping plants achieve predictable budgeting, stronger return on investment, and smoother production planning across varying batch volumes each cycle.

Consumption ranges 45–75 kW/m³ (needs verification). Efficient torque decreases waste energy. It stabilizes power load. This controlled efficiency improves sustainability, limits unnecessary heat buildup, protects sensitive formulations, and supports compliance targets while keeping operational performance within optimal electrical consumption margins during continuous production runs daily.

Scheduled inspections prevent failure. Proper lubrication preserves components. KARVIL offers robust spare part solutions for ease. Regular maintenance planning increases safety, extends service life, and ensures consistent performance under heavy load conditions, allowing teams to minimize disruption risks, optimize workflow efficiency, and maintain equipment reliability standards.

| Factor | Standard Mixer | KARVIL Sigma Mixer |

|---|---|---|

| Downtime | High | Low |

| Output Stability | Medium | High |

| ROI | Average | Strong |

Choosing the right Sigma Mixer requires clear alignment between material demands and engineering precision. We verify torque balance and speed control to secure reliable processing performance. We confirm viscosity, match blade design, and validate torque to ensure stable, efficient performance. This approach supports consistent output and long-term production value. Poor selection causes downtime and rising costs, but KARVIL Sigma Mixer solutions deliver durable, high-value reliability. They provide expert support and customized configurations for demanding high-viscosity production environments.

A: A Sigma Mixer blends dense, sticky compounds using high torque and controlled kneading to ensure uniform texture and stable flow.

A: Match blade type, torque range, and capacity to material viscosity for reliable Sigma Mixer performance and reduced downtime.

A: A Sigma Mixer maintains low speed and high torque, preventing overheating and improving consistency in hard-to-mix batches.

A: Capacity, motor power, heating features, and durability influence the Sigma Mixer price and long-term operational savings.

A: Check fill volume, blade clearance, and torque settings to restore smooth Sigma Mixer operation and eliminate dead zones.

A: Yes, hygienic designs and stainless steel construction make Sigma Mixers ideal for regulated production environments.

A: It shortens mixing cycles, lowers energy waste, and ensures consistent output quality.

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.