Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

About the Client and Project

In 2025, Karvil Machinery successfully completed a 3500 L health-supplement powder production line for a long-term customer in the United States.

The client is a professional producer of nutritional and dietary supplements, specializing in protein powders, vitamin blends, collagen products, and herbal mixtures. With the rapid growth of the health and fitness market, their production demand increased significantly, and they needed a complete system to handle large batches of high-quality powders.

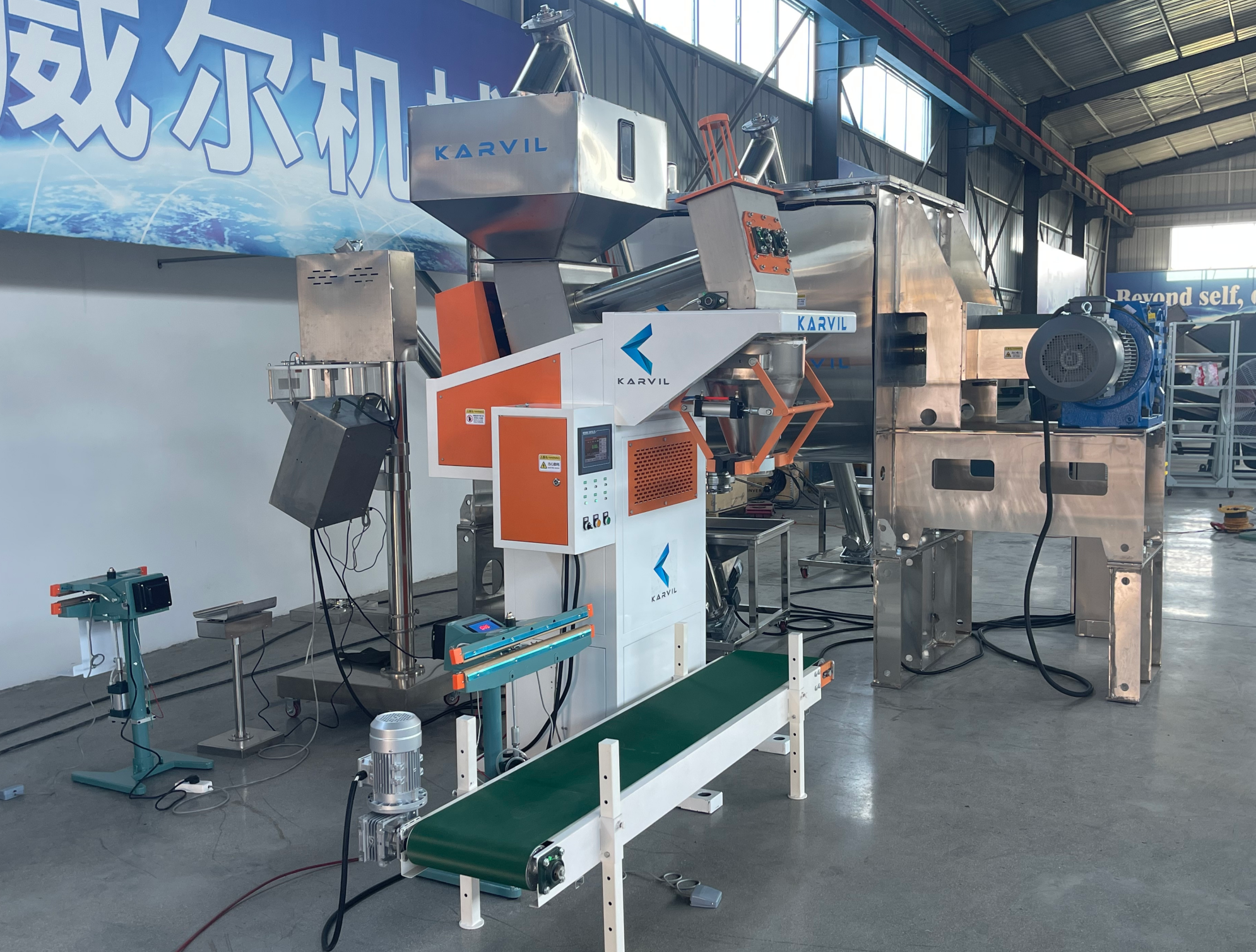

The full production line we provided included:

One 3500 L horizontal ribbon mixer, full SS304

Three screw conveyors for automatic material transfer

One large-capacity packaging machine

One small-capacity packaging machine

Two sealing machines

Each unit was integrated with a control system, designed for stable operation, dust-free production, and easy maintenance. All contact parts were made of SS304, ensuring long service life.

Why Health-Supplement Powders Matter

Health-supplement powders have become one of the most popular product forms in the global nutrition market. They provide a convenient way for consumers to maintain daily wellness by filling nutritional gaps that cannot be met through food alone.

Powder supplements—such as protein, vitamins, probiotics, and herbal extracts—help with muscle recovery, improve metabolism, and boost immunity. Compared with tablets or capsules, powders are more versatile, faster to absorb, and easier to customize with different ingredients.

The global demand for such products continues to grow as consumers become more health-conscious. For manufacturers, this trend brings both opportunity and responsibility—to ensure clean, efficient, and safe production processes. That’s why choosing a reliable production partner is crucial.

At Karvil Machinery, we understand these needs. Over the past decade, we have provided advanced mixing and packaging systems for food, supplement, and pharmaceutical producers around the world, helping clients achieve both productivity and quality assurance.

Client’s Questions and Our Responses

Before confirming the order, the U.S. customer asked several key technical questions. We provided clear, practical answers to ensure full understanding of every detail.

1. Installation Concerns

Customer: We don’t have professional technicians here. Is the installation complicated?”

Karvil: “Not at all. The machines are designed for easy assembly. Each connection point is clearly marked, and the user manual includes detailed installation steps. You just need to fix the equipment in place and connect the power cable to the control cabinet. Once power is on, the line can start working directly. No special tools or technicians are required.”

2. Material Choice for the Mixer

Customer: “Should I use stainless steel or carbon steel for the mixer?”

Karvil: “For your product—health-supplement powders—we highly recommend full stainless steel 304. It prevents contamination, resists corrosion, and is easy to clean. Carbon steel is a more economical option but better suited for non-food industrial materials. .”

3. Packaging Solutions

Customer: “Can you provide packaging machines too?”

Karvil: “Of course. We offer both large and small packaging machines. Please tell us your bag type and target weight per bag—1 kg, 5 kg, or 25 kg—and we’ll recommend the most suitable model. ”

4. Voltage Customization

Customer: “Can I change the voltage before shipment?”

Karvil: “Yes, definitely. You can change the voltage condition anytime before production starts. Whether 480 V 60 Hz three-phase or 220 V single-phase, we can customize it for free. Before we begin manufacturing, we’ll reconfirm all technical details with you.”

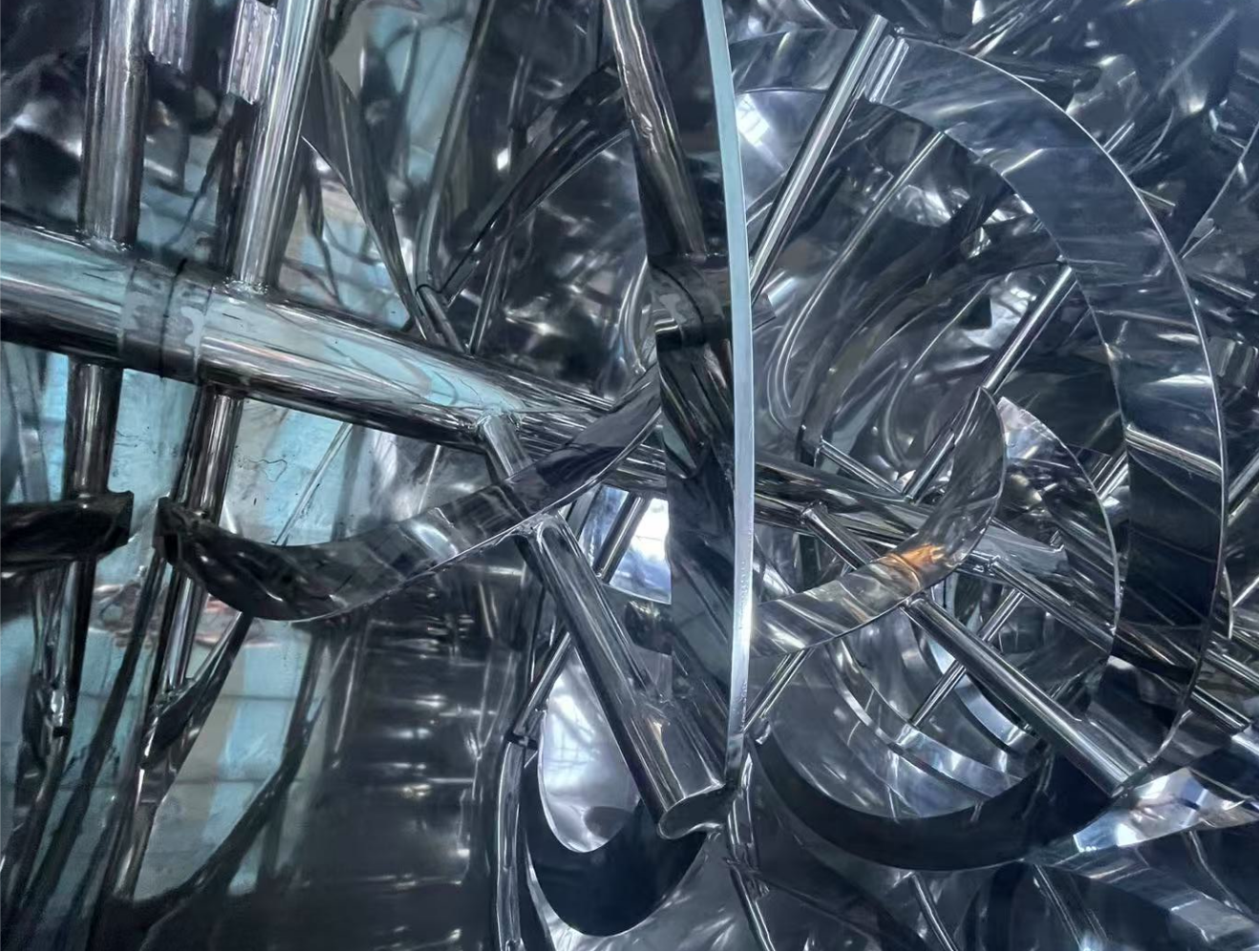

Design and Manufacturing

Once the project was confirmed, our engineering team prepared detailed drawings. The 3500 L ribbon mixer was built with a double-ribbon structure for efficient and uniform blending of powders with different densities. The inner and outer surfaces were mirror-polished to achieve a smooth, easy-clean finish.

The three screw conveyors were designed to transfer powder automatically between ribbon mixer and packaging machines, reducing labor and dust.

During assembly, every machine underwent strict quality inspection, including welding checks, electrical testing, and load simulation. The final factory test video was shared with the client, showing real operation, mixing speed, and sealing performance.

After testing, the entire production line was loaded into a 20-foot container and shipped from Qingdao Port to the United States. The package included an operation manual, wiring diagram, spare parts, and a list of consumables to facilitate easy installation for the customer.

Upon receiving the goods, the customer completed assembly within two days following the steps in the installation manual. They stated that the entire process was very smooth and required no specialized technicians. Clear labels on each component and the modular design made installation extremely simple.

Customer Feedback and Results

After installation, the production line underwent a week of continuous trial operation. The customer was extremely satisfied with its performance. The mixing quality was excellent, achieving uniform mixing. The screw conveyor transported materials smoothly without leakage.

The packaging system can improving production flexibility and efficiency. The customer also praised the production line for its quiet operation, ease of cleaning, and significant savings in labor and maintenance time.

They commented:

“We were surprised by how easy it was to install and operate the whole line. The mixing quality is excellent, and the packaging accuracy is perfect. Karvil’s technical support made everything very clear from start to finish.”

Why the Client Chose Karvil

1. Over 10 years of experience in food and supplement mixing systems

2. Proven design for high-capacity production lines

3. Full SS304 construction meeting FDA/GMP standards

4. Easy installation and user-friendly control

5. Fast and responsive communication throughout the project

6. Customized voltage, layout, and packaging options at no extra cost

7. Reliable after-sales service with spare parts and video support

This 3500 L health-supplement powder line marks another successful project for Karvil Machinery in the U.S. market. By focusing on customer needs, technical precision, and service transparency, we delivered not just machines but a complete solution for modern supplement manufacturing.

From the first technical discussion to the final trial run, our goal remained the same—to make equipment simple, efficient, and reliable for every client.

Karvil Machinery continues to work with international partners to build intelligent, hygienic, and energy-efficient mixing and packaging systems. Whether for health supplements, food powders, or industrial materials, our promise stays constant: quality you can trust, service you can feel.

frank@karvil.com

www.sigmazs.ccom

content is empty!

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.