Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

If you are processing materials like silicone rubber, heavy adhesives, or chewing gum base, you already know the problem: standard mixers just can't handle the torque.

When viscosity gets high, ordinary agitators get stuck, motors burn out, or worse—you get a mix that is uneven and full of lumps.

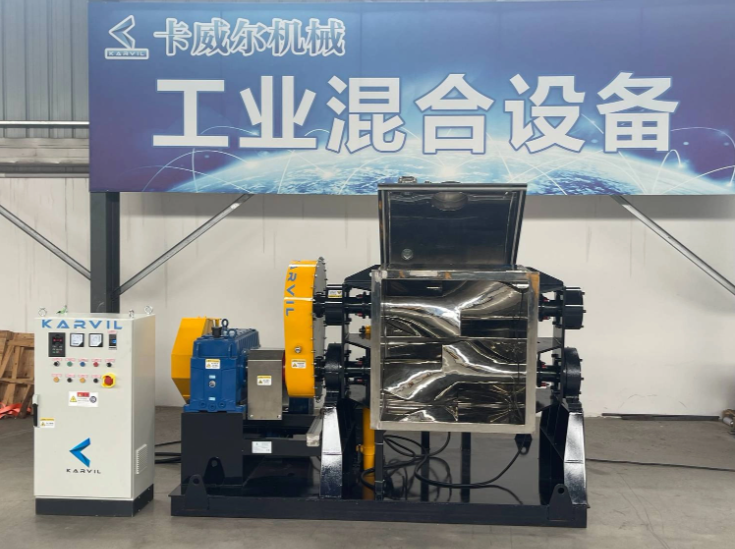

That is where the Sigma Kneader (Z-Blade Mixer) comes in. It isn't a new fancy gadget; it is the workhorse of the heavy chemical industry. At karvil machinery, we build kneaders that are designed to take a beating and keep running, shift after shift.

The concept is simple but effective. Inside the W-shaped trough, two heavy-duty "Z" shaped blades rotate toward each other at different speeds.

This creates a massive amount of shearing force. Imagine stretching a piece of dough and folding it over, again and again. That is what our machine does, but with thousands of pounds of force. It physically shears the material against the walls and pulls it apart, ensuring that every bit of powder or liquid is fully integrated into the base.

It’s ideal for:

High Viscosity materials (up to 5,000,000 cps).

Materials that need to be heated or cooled while mixing.

Processes that require vacuum (to remove air bubbles).

We know you have options, but here is why our clients stick with us:

High torque means high stress. If the gearbox is weak or the steel is thin, the machine will warp over time. We use reinforced stainless steel (304 or 316L) and oversized gearboxes to ensure the machine remains stable, even when mixing the stiffest rubber compounds.

The hardest part of mixing sticky stuff is getting it out of the machine. We offer three ways to solve this:

Screw Extrusion (Most Popular): A screw at the bottom pushes the material out directly into a shape or to the next step of production. No manual scraping required.

Hydraulic Tilt: The whole bowl tips over to dump the batch.

Bottom Valve: Good for materials that can flow on their own.

Whether you are making hot melt adhesives that need to stay hot, or friction materials that need to stay cool, our jacketed bowls allow for precise circulation of steam, oil, or water.

Our machines are currently running in factories producing:

Sealants & Rubber: Silicone rubber, butyl rubber, hot melt glue.

Chemicals: BMC/DMC molding compounds, cellulose.

Food: Chewing gum bases, heavy doughs, sugar pastes.

Batteries: High-viscosity electrode slurries.

You don’t need a sales pitch; you need a machine that works.

Tell us what you are mixing and what your capacity requirements are. We will suggest the right blade speed, power, and discharge method for your specific line.

frank@karvil.com

content is empty!

Karvil has a professional technical team dedicated to the research, design, and manufacturing of Sigma mixers and ribbon blenders. Our equipment has already been sold to over 50 countries and various industries worldwide.